C3-V2.7: General concepts for strengthening of structural members

Table of contents

Project data

| Titel | Title TP C3-V2.7-Ia: Bemessungsmodelle und Materialspezifikation im Verbundvorhaben C3-V2.7: Erstellung von Gesamtkonzepten für die nachträgliche Bauteilverstärkung mit Carbonbeton | SP C3-V2.7-Ia: Design models and material specification as part of the joint research project C3-V2.7: Development of a general plan to strengthen an existing concrete structure with carbon reinforced concrete Förderer | Funding Bundesministerium für Bildung und Forschung (BMBF); Projektträger: FZ Jülich GmbH / C3 – Carbon Concrete Composite Zeitraum | Period 05/2017 – 10/2020 Leiter | Project manager Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach Bearbeiter | Contributors Dipl.-Ing. Egbert Müller, Dipl.-Ing. Sebastian May, Dipl.-Ing. Tilo Senckpiel-Peters Projektpartner | Project partners Institut für Massivbau, RWTH Aachen University | Ingenieurbüro Grassl GmbH, Berlin | Technologie- und Entwicklungszentrum Groz-Beckert KG, Albstadt | Hörnig Bauwerkssanierung GmbH, Aschaffenburg | Torkret GmbH, Essen | Betonfertigteile G. Quadflieg GmbH, Naumburg |

Report in the annual report 2019

QUERKRAFTVERSTÄRKTE PLATTENBALKEN

Test setup for strengthened T-beams

The project C3-V2.7 is in the third year and many large component tests have already been carried out. First of all, reinforced concrete plates designed for bending were strengthened with carbon concrete. Under the selected boundary conditions, i.e. with a low steel reinforcement ratio and concrete of strength class C50/60, a load increase of up to 400% could be achieved with the carbon reinforcements used in a single reinforcement layer. If two layers of carbon reinforcement are applied, a further load increase is possible. Instead of bending failure, a combination of bending failure, shear failure and delamination of the carbon concrete layer occurs. A similar failure behaviour can be observed with a higher steel reinforcement ratio and with two layers of carbon reinforcement.

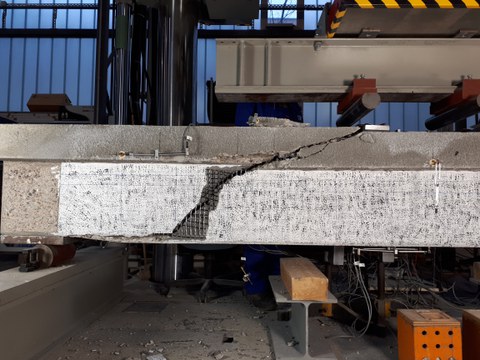

A shear strengthening made of carbon concrete was investigated on slender and compact T-beams with one or two layers of carbon reinforcement and with one layer of shotcrete only. The reinforcement was applied either laterally to the web or by means of L-profiles surrounding the entire web. The fibre strands were oriented at 0/90° or ± 45/45° angle to each other.

With a pure shotcrete layer, a load increase of about 10% could be achieved for the slender T-beams. When using carbon reinforcement, strengthening of the webs at its lateral surface only increased the load resistance by 40%, irrespective of the carbon reinforcement, the fibre strand orientation or the number of layers. If the carbon reinforcement was implemented using L-sections, a load increase of 45% was possible. The failure mechanism was a delamination of the carbon concrete layer from the old concrete.

Shear failure of a T-beam

The load-bearing behaviour differed for the non-slender T-beams. If the webs were reinforced laterally with Wilhelm Kneitz or solidian carbon reinforcement, the ultimate load increased by approx. 20%. However, bending compression failure occurred, in which the necking of the concrete compression zone became decisive. If the reinforcement was carried out with the solidian GRID Q85/85-CCE-21 carbon reinforcement (orientation: 0/90°, single layer), laterally or enclosing the web, the ultimate load increased by approx. 35%. This resulted in a bending shear failure.

Report in the annual report 2018

SUCCESSFUL COMPONENT TESTS

Herstellung biegeverstärkter Stahlbetonplatten mit Carbonbeton

Within the main C³-project (Carbon Concrete Composite) there are various subprojects. One of these is called C3-V2.7 and the main task of this projects is to develop “Overall concepts for the retrofit of components with carbon reinforced concrete”. To create those concepts two research institutions and five business partners collaborate. In cooperation with the project C3-V1.2 “Verification and testing concepts for standards and approvals” a lot of large-scale component tests will be carried out and existing formulas verified and, if necessary, adjusted.

There are regular exchanges between business and research partners on all relevant work results to achieve a practice-oriented concept at the end. The first step in the project C3-V2.7 was to write a paper that includes existing formulas of strengthened reinforced concrete structures and afterwards, monitored by business partners for their manageability. Second, the planning for the component tests began. The bending behaviour of carbon reinforced concrete was carried out on a reinforced concrete plate cross section. During the tests the amount of reinforcement layers and the reinforcement material varied. A four point bending test was used to examine the load-bearing behaviour and a load increase of 400 % could be determined.

Prüfung eines biegeverstärkten Plattenquerschnittes

At present, T-beams are being used to examine the shear strengthening reinforced concrete. Besides a variation of the carbon reinforcement two different geometries of the T-beam are investigated. With regard to the mechanical properties of the carbon reinforcements the lateral web surfaces were reinforced as well as lateral and below the web. Reinforcement works were carried out with regard to their practicality. After doing the strengthening work the components were tested at the Otto Mohr Laboratory and first results have shown a load increase of about 150 % compared to the original ones. Based on these results, a mechanical design model will be created.

Report in the year book 2017

GENERAL REINFORCEMENT CONCEPTS

Tools to design the strengthening layer

How to strengthen buildings in a sustainably and efficiently manner? The partners in the C3-project “Overall concepts for the retrofit of components with carbon concrete” address this question. The project is a joint project with five partners from industry and another research institution, and it will be completed within the common research project C3 – Carbon Concrete Composite. In previous research and practical projects, the strengthening of different kinds of components such as columns, ceiling slabs, and beams with textile reinforced concrete has already been successfully demonstrated. On the basis of experimental investigations, calculation models and safety concepts were developed to provide guidelines on how to strengthen various components in practice.

It is now time to merge the recommendations for loads and design concepts already developed into a coherent catalog, and then to develop an overall concept for reinforcing measures for different components and load types. To achieve this goal, first, all existing component-specific reinforcement concepts had to be compiled. The formulas are to be prepared in a practice-oriented manner. In the next step, the existing component concepts are to be discussed in coordination with industry partners and tested using the know-how of industry partners to determine whether all the usual proofs have been considered in the proposed formulae for the respective reinforcement measure, or whether further proofs are to be included if necessary.

After the development of an overall concept for strengthening measures of reinforced concrete components with carbon concrete, tests will be carried out on specific component cross-sections. These are intended to confirm or validate the various aspects of the recommendations for loads and design, such as the safety concept and the load-bearing behaviour or failure mechanisms. If the component tests reveal an unpredictable material behaviour, which may be the case if new material combinations are used, the concept for the part-specific reinforcement measure must be tested again and, if necessary, additional verification procedures must be added.

At the end of the project, a complete overall concept for the reinforcement of reinforced concrete elements with carbon concrete will be available for use in construction.