Design process for offshore structures

Table of contents

Project data

| Titel | Title TP B01: Integrierter Entwurfsprozess für Offshore-Tragstrukturen | Project B01: Integrated design process for offshore structures Förderer | Funding Deutsche Forschungsgemeinschaft (DFG) / SFB 1463 Zeitraum | Period 01/2021 – 12/2024 |

Report from year book 2023

Feature selection for offshore jackets

Rambøll- jacket for the digital twin in CRC 1463

One main objective of the project is to develop a data-driven method for jacket conceptual design, which can automatically predict structural parameters for jacket based on certain boundary condition variables using machine learning (ML). A novel dataset of completed and under-construction jackets worldwide was established as the cornerstone for ML applications. In 2023, the project focused on investigating comprehensive feature selection approach, which is crucial for identifying and visualizing correlations among features and feature importance for interpretable data-driven design. The results of feature selection are appropriate input feature subsets for predicting each target feature of jacket structural parameter.

We investigated a multi-criterion fusion approach to enhance the robustness of feature selection, aiming to yield consistent subsets despite training data variations like sample additions or deletions. This approach integrates multiple feature selection evaluation algorithms through a ranking-based fusion technique. For regression tasks, evaluation algorithms include ANOVA F-test, Spearman’s correlation, mutual information, tree-based algorithm, and Elastic Net, while classification tasks employ ANOVA F-test, relief algorithm, mutual information, tree-based algorithm, and fast correlation-based filter. Subsequently, random forest and eXtreme gradient boosting models were trained using these selected feature subsets to predict individual jacket structural parameters. The improved predictive performances of these models demonstrated the effectiveness of the feature selection in capturing essential patterns and characteristics of well-designed jackets, thereby improving the accuracy and efficiency of the conceptual design process.

The selected feature subsets are now used to develop promising ML-based predictive models for establishing an integrated data-driven design framework. In 2024, the research will focus on improving the predictive performance of the framework using generative models.

Report from year book 2022

Database for offshore jacket substructures

Model of the offshore jacket substructure for hydrodynamic tests

Compared to “normal” building structures, the substructures of offshore wind turbines (OWT) are unifunctional structures whose main task is to transfer loads. The structural design of OWT is generally based on explicit theoretical and practical knowledge as well as on the engineers’ intuition. Therefore, the calculation methods for offshore substructures (OSS) have been developed over the past decades. The conventional methods for designing OSS are based on the structural assessments in ultimate limit states, fatigue limit states and accidental limit states, which only consider a small aspect of the life process of the structure. With the higher demands of power classes of OWT, there are more influence factors throughout the life cycle that determine the quality of structural design of OSS. Therefore, large amounts of design data are required in the integrated design process, e.g. structural data, site conditions, information of transport and installation vessels, information of rotor-nacelle assembly and tower, etc.

With the rapid development of artificial intelligence technologies, machine learning (ML) algorithms show advantages in handling large amounts of data in multi dimensions and can identify the complex internal correlations between features. In order to accumulate the design data and apply experience from existing OWT projects as well as the intuitions of engineers in the field of offshore wind industry, it is thus meaningful to develop a data-based ML model to evaluate the design quality of OSS. The current work focuses on the first step for developing the ML model, which is to create a database of existing jacket OSS in different wind farms around the world and to augment the database with new realizations based on the existing design data of OSS. Furthermore, data points for each jacket OSS designs will be generated for holistic evaluations from experts and engineers in this field. The evaluation output should be in the form of quality level or scores for each OSS design and used as labels in the database.

Report from year book 2021

Structural design with machine learning

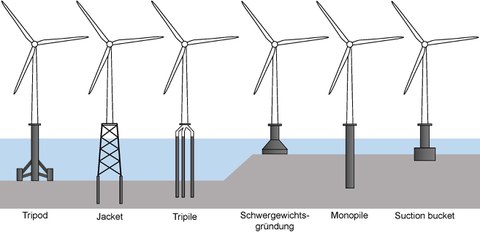

Offshore substructure types in wind farms with different water depths

The research project B01 is processed within the framework of the Collaborative Research Center (CRC 1463). The objective of the CRC 1463 is the investigation of physical and methodological fundamentals, based on the concept of the digital twin, for an integrated design and operation methodology of future offshore megastructures. Offshore megastructures are understood as slender integral structures of offshore wind turbines (OWT), which are characterized by very large dimensions and masses as well as by strong dynamic interactions with their environment. They can make a significant contribution to the success of the energy transition by ensuring more efficient power generation and more continuous power feed-in compared to today’s turbines. With the requirements of higher rated power and larger dimensions, boundary conditions from manufacturing, installation or maintenance have an enormous influence on the feasibility and economic efficiency of OWTs. The design of these support structures must incorporate all aspects of the life cycle process.

The objective of B01 is to describe the investigation of the load-bearing behaviour with a design process that takes into account the important life cycle influencing factors. Furthermore, the structural design is not only based on explicit theoretical and practical knowledge such as standards and codes, but also on the intuition of engineers. How to incorporate this intuition into the structural design process by using appropriate machine learning (ML) techniques is a key task of the project.

In this integrated design process, previous design experience and approaches are combined with ML methods to create a predictive model that can be used to forecast the overall design quality under different design variations. In this context, a database of realized and simulated designs of the OWT needs to be developed and used to train the ML model. So far, the analysis of the OWT life process has been done through an extensive literature review of standards, guidelines and other relevant publications. These factors are systematically organized and parameterized in the form of features that characterize the individual life phases of OWTs.