Fatigue in wind energy plants

Table of contents

Project data

| Titel | Title TP Ermüdungsverhalten von druckschwellbeanspruchtem Beton sowie Stahl- und Spannbetonbauteilen mit und ohne trockene Fugen im Verbundvorhaben WinConFat-Structure: Bauteilermüdung von Windenergieanlagen aus Stahlbeton und Spannbeton unter hochzyklischer Beanspruchung | Subproject Fatigue behavior of concrete subjected to compressive fatigue loads as well as reinforced and prestressed concrete components with and without dry joints within the joint research project WinConFat-Structure: Fatigue of components of wind turbines made of reinforced and prestressed concrete under high cyclic loading Förderer | Funding Bundesministerium für Wirtschaft und Klimaschutz (BMWK) Zeitraum | Period 05/2022 – 04/2026 Verbundvorhaben- und Teilprojektleiter | Leader of joint and subproject Prof. Dr.-Ing. Steffen Marx Team | Team Dennis Birkner, M.Sc., Dipl.-Ing. Clara Schramm, Dipl.-Ing. Florian Fürll Projektpartner | Project partners Institut für Massivbau, Leibniz Universität Hannover, | Institut für Massivbau, RWTH Aachen University | Bundesanstalt für Materialforschung und -prüfung (BAM), Abteilung 7 Bauwerkssicherheit, Berlin Assoziierte Partner | Associated partners Deutscher Ausschuss für Stahlbeton (DAfStb), Berlin | Deutscher Beton- und Bautechnik-Verein E.V. (DBV), Berlin | e.disnatur GmbH, Potsdam | H+P Ingenieure GmbH, Aachen | Max Bögl Bauservice GmbH & Co. KG, Neumarkt | Nordex SE & Co. KG, Hamburg | TÜV Nord EnSys GmbH & Co. KG, Hamburg | Vallen Systeme GmbH, Icking |

Report from the yearbook 2023

Fatigue tests on structural elements of wind turbines

Reinforcement cages of the beam specimens

As part of global efforts to reduce CO2 emissions, the use of renewable energy sources, especially wind energy, plays a significant role. While 15 years ago, the share of electricity generated from wind energy, for example, in Germany, was only 6 %, by the year 2022, this share had already reached 22 % and is expected to grow.

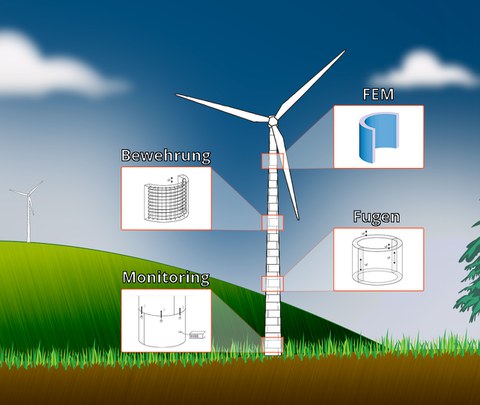

In the case of onshore wind turbines, hybrid towers are the most common construction type. They consist of a concrete foundation onto which concrete segments are stacked up to about 2/3 of the hub height. With an adapter construction, a steel tower is connected above for the final third, on which the nacelle is placed. The concrete segments are prefabricated components with ground joints. They are dry-stacked on-site and afterwards externally prestressed using tendons located within the tower. To facilitate the transportation of the segments, which also grow larger with increasing tower height, they are often designed as half or third shells. In this construction method, reinforced concrete accounts for approximately 75 % of the total mass of an average wind turbine. As these structures are often mass-produced in large quantities, significant material savings can be achieved even with minor cross-sectional optimizations.

Experimental and numerical investigations of reinforced concrete structures with and without dry joints are planned in order to analyze the potentials in load-bearing capacity. In the first step, based on the results of the previous project “WinConFat”, the fatigue behavior of prestressed reinforced concrete beams with different degrees of reinforcement will be investigated. As a special feature, fiber-optic sensors are bonded to the longitudinal reinforcement in several beams and inserted freely in the concrete between the reinforcement layers. These distributed sensors are used to record the strain and stress redistributions inside the cross-section as a result of material degradation. This view into the interior of the components provides valuable information for the calibration of the numerical model. The findings will be used to formulate recommendations for adapting the current design concept for reinforced concrete structures subjected to fatigue loading and joints subjected to cyclic compressive swell and shear stresses.

Report from the yearbook 2022

Fatigue of wind energy turbines

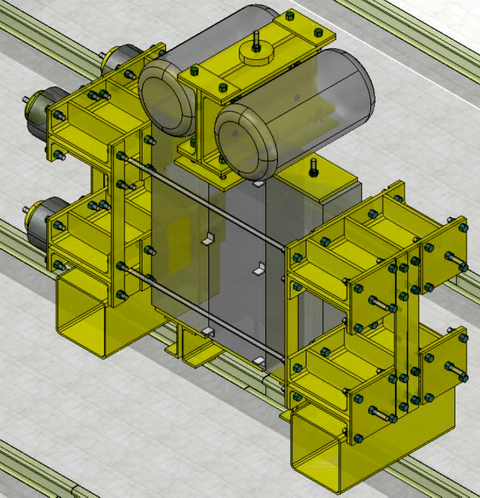

Planned test setup for experiments on dry joints

A key element in reducing greenhouse gas emissions is the extension of renewable energies, with wind energy playing a leading role. In this context, not only the efficient operation of wind turbines is important, but also the resource-efficient production of tower structures. The extensive fatigue tests carried out on normal and high-strength concrete in the previous joint research project WinConFat (FKZ 0324016) were focused on the material level. For the application in design standards, additional analyses on structural components beyond the pure material investigations are demanded by the regulatory authorities. In the 2022 started sub-project of the joint project WinConFat-Structure, this still outstanding transfer of results from the material level to the component or structure level is addressed.

The focus is on three topics. The first research focus is on the influence of reinforcement on the fatigue resistance of overcompressed structural components. The results from fatigue tests on large-scale reinforced concrete beams are transferred into numerical models. The 2nd main research focus is on the fatigue behavior of dry structural joints. Systematic experimental and numerical investigations deliver information in order to analyze the influence of fatigue loaded horizontal and vertical joints in wind turbines on the load-bearing behavior. The application of the proven resonance-based testing technology makes investigations in the necessary high cycle fatigue range possible. The specimens are beams and blocks with dry joints each which are compressed by prestressing. In the third research focus, a stochastically based evaluation of the fatigue behavior of concrete subjected to compressive swell loading is to be carried out in order to optimize the existing safety concept.

At the end of the project, recommendations for design concepts with regard to the respective focal points are to be developed from all three research focuses. The involvement of the Deutscher Ausschuss für Stahlbeton (DAfStb, German Committee for Steel-reinforced Concrete) and Deutscher Beton- und Bautechnik-Verein E.V. (DBV, German Concrete and Construction Technology Association E.V.) as associated partners will ensure the transfer of the recommendations into design practice.

Short description

Research focus in WinConFat-Structure

A key element in reducing greenhouse gas emissions is the extension of renewable energies, with wind energy playing a leading role. In this context, not only the efficient operation of wind turbines is important, but also the resource-efficient production of tower structures. The extensive fatigue tests carried out on normal and high-strength concrete in the previous joint research project WinConFat (FKZ 0324016) were focused on the material level. For the application in design standards, additional analyses on structural components beyond the pure material investigations are demanded by the regulatory authorities. In the now approved sub-project of the joint project 'WinConFat-Structure', this still outstanding transfer of results from the material level to the component or structure level is addressed.

The focus is on three work packages. The first research focus deals with the influence of reinforcement on fatigue life in overcompressed structural components. The second main research focus is on the fatigue behavior of dry structural joints. For this purpose, systematic experimental and numerical investigations are to be carried out in order to analyze the influence of fatigue loaded horizontal and vertical joints in wind turbines on the load-bearing behavior. In the third research focus, a stochastically based evaluation of the fatigue behavior of concrete subjected to compressive swell loading is to be carried out in order to optimize the existing safety concept. At the end of the project, recommendations for design concepts with regard to the respective focal points are to be developed from all three research focuses. The involvement of the DAfStb and DBV as associated partners will ensure the transfer of the recommendations into design practice.