Investigation of process parameters during ultrasonic cutting of foods

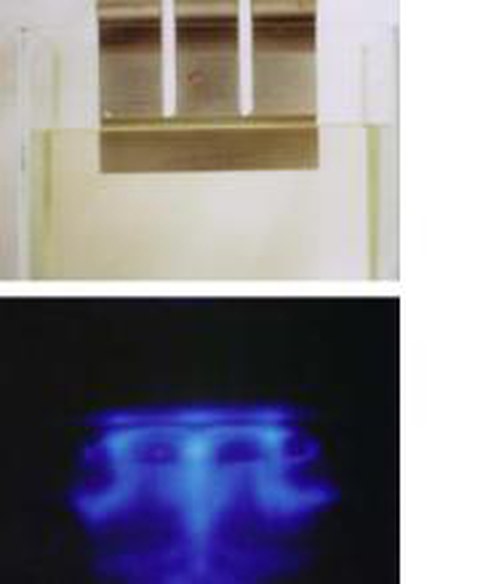

In many fields of the food processing industry the appearance quality of foods is often determined by a cutting process. In conventional cutting, quality defects and a poor accuracy of the cut may occure, in spite of a careful adjustment of technological parameters with respect to the properties of the food to be cut. Ultrasonic cutting is a possible alternative by some advantages:

- excellent quality of the cut face, even for strongly adhesive and multilayered products,

- significant reduction of cutting force and product deformation,

- lower amount of crumbs and debris, and

- longer intervals between cleaning and sharpening of the blades.

The aim of this project is to expand the potential of ultrasonic cutting applications in food production, especially for products where conventional cutting leads to unsatisfying results. Studies are focused on

- estimation of quality improvement when applying different cutting parameters like amplitude, frequency and cutting velocity;

- determination of secondary effects as influenced by the product under study including aspects of food safety, and

- evaluation of alternative design concepts of ultrasonic cutting devices.

In cooperation with:

- Institute of Non-Classical Chemistry e. V. at the Universität Leipzig

- Institute of Processing Machines and Technology and Agricultural Engines, Technische Universität Dresden

Supported by:

- Industrievereinigung Lebensmitteltechnologie und Verpackung (IVLV) e.V., Munich

Project researchers and contact:

- Rohm

© Surber

© Surber

Dr.-Ing. Yvonne Schneider

Product technologies: Confectionary; Process engineering: Cutting

Send encrypted email via the SecureMail portal (for TUD external users only).

© Surber

© Surber

Research Assistant

NameDr.-Ing. Susann Zahn

Food Process Engineering, Food Design

Send encrypted email via the SecureMail portal (for TUD external users only).