Nov 28, 2024

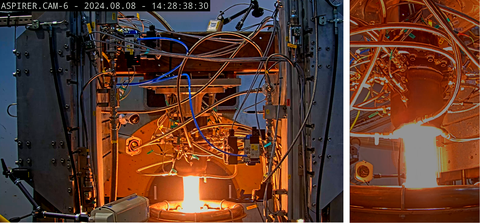

3D printing meets space travel: First successful test of an aerospike engine made via additive manufacturing and powered by hydrogen peroxide-kerosene fuel

Author: Verena Nowatzky

The Space Transportation Systems group at the Chair of Space Systems at TU Dresden has achieved a breakthrough in space technology. As part of the ASPIRER project funded by the European Space Agency (ESA), the scientists successfully carried out the world's first hot gas test of a 3D-printed aerospike engine using a more sustainable fuel combination of highly concentrated hydrogen peroxide and kerosene. The project is being carried out in cooperation with the Fraunhofer Institute for Material and Beam Technology IWS, ArianeGroup, and the Warsaw Institute of Aviation.

Compared to conventional rocket engines with bell nozzles, aerospike engines save a significant amount of fuel and score highly in terms of efficiency. However, they are also more complex and more difficult to control.

During the test campaign, the engine ran both in monopropellant mode with only one type of fuel, and in bi-propellant mode with both types. The monopropellant mode involves hydrogen peroxide being decomposed by an integrated chemical catalyst at high temperatures. Only water vapor and oxygen remain as end products, making the fuel a more environmentally friendly alternative to conventional fuels. With the bi-propellant mode, on the other hand, kerosene is injected, causing the mixture to ignite spontaneously without the need for additional mechanical components. The engine is designed for an operating pressure of 20 bar and delivers 6 kilonewtons of thrust at full load. One kilonewton is roughly equivalent to the weight of a mass of 100 kilograms.

The main challenge with aerospike engines is the cooling. It is only through the use of additive manufacturing in the form of modern 3D printing processes such as Laser Powder Bed Fusion (LPBF) that these engines can be designed and manufactured effectively. The scientists also successfully tested a newly developed, heat-resistant ceramic coating for the combustion chamber elements.

Thanks to their lightweight and compact design, aerospike engines are suitable for various mission scenarios, such as launch vehicles, expeditions to Mars and Saturn's moon Titan, or lunar modules. Especially in the latter application scenario, aerospike engines could represent a more sustainable alternative to conventional, hydrazine-based engines, the use of which is viewed critically due to health and environmental risks. The special shape of the engines also allows for greater leeway in design, so that lunar modules can be built flatter. This simplifies loading and unloading by astronauts and the deployment of rovers.

Moreover, the Institute of Aerospace Engineering is investigating the suitability of alternative methods for controlling the engines, as well as their advantages over conventional systems. In the long term, the aim is to overcome the low level of technological maturity and the related uncertainties associated with aerospike engines.

Contact

Dr. Christian Bach

Chair of Space Systems

Institute of Aerospace Engineering

Phone: 0351 463-38722

E-Mail:

Web: Space Transportation Systems - Chair of Space Systems - TU Dresden