Jan 05, 2024

How to capture water from air

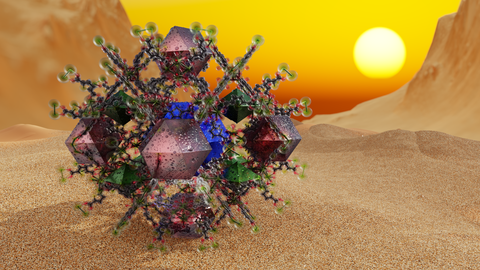

Metal-organic frameworks can adsorb water in the pores they form. The picture shows the three different types of interconnected cavities of the studied compounds as polyhedra.

Researchers decipher the underlying adsorption mechanism of special microporous material

Researchers from the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and Dresden University of Technology (TUD) have unraveled the water adsorption mechanism in certain microporous materials – so-called hierarchical metal-organic frameworks (MOFs) – while probing them on the atomic scale. Discovered only about 25 years ago, their special properties quickly led to a reputation as “miracle materials” – which, as it turned out, can even harvest water from air. In the journal ACS Applied Materials & Interfaces, the researchers describe how the material achieves this.

“These very special materials are highly porous solids made of metals or metal-oxygen clusters which are connected in a modular way by pillars of organic chemicals. This 3D arrangement leads to networks of cavities reminiscent of the pores of a kitchen sponge. It is precisely these cavities that we are interested in”, says Dr. Ahmed Attallah of HZDR’s Institute of Radiation Physics. Those nanoscale pores are the foundation for the cornucopia of potential applications, ranging from gas storage to separation technology as well as catalysis and novel sensors – and water harvesting as one of the most promising.

Probing the void

For that matter, the team synthesized two MOFs based on the metals zirconium and hafnium, hold in place by the same organic framework. Then, the scientists had a deeper look into the characteristics of the obtained materials by applying a variety of complementary techniques. On the one hand, they determined how much nitrogen or water vapor could be trapped in the pores of the material. On the other hand, they had a closer look at the exact mechanism of water adsorption in MOFs, which to this date was not well understood. “To shed light on the process, we used a non-destructive technique known as positron annihilation lifetime spectroscopy, or in short, PALS, in which a positron will interact with electrons – its antiparticles – thereby annihilating, and then releasing gamma rays that can be detected. The time between the emission of positrons stemming from a radioactive source and the subsequent detection of gamma rays is the positrons’ lifetime. This in turn depends on how fast they meet electrons”, Dr. Andreas Wagner, head of the ELBE Center for High-Power Radiation Sources at HZDR describes the principle.

If voids are present in the material, like nanopores, positrons and electrons tend to form so-called positronium atoms, with one electron and one positron each, orbiting around their common center of mass, going straight at each other until the pair of particles is either scattered or annihilated, whichever comes first. Since these exotic atoms live longer in larger voids, they are revealing information about the void´s size and distribution. The researchers found that the water adsorption in the MOFs was mainly governed by a stepwise filling mechanism, including formation of liquid bridges in the pores. The water adsorption was influenced by the formation of water clusters on the pore surface, which created small air gaps in the pores.

Squeezing out desert air

“Due to the close chemical resemblance of the metals zirconium and hafnium, the resulting metal-organic frameworks have the exact same pore sizes and high chemical stability, allowing us evaluating the validity of our method at the same time”, Prof. Stefan Kaskel, Chair of Inorganic Chemistry I at Dresden University of Technology, explains. His group’s research focuses on the development of novel functional materials for various applications, such as energy storage and conversion, environmental catalysis and water adsorption.

Based on the results, the researchers conclude that their study provides new insights into the water adsorption mechanism in hierarchical MOFs, which could help design better materials for water harvesting from air, which is particularly important in arid regions. By exposing MOFs to air, they can capture water molecules from the atmosphere. Then, by applying heat or reducing the pressure, the water can be released and used. The scientists already think further ahead: Is the technology suitable for commercial solutions? 1.3 liters of water per kilogram of MOF per day from desert air, as reported by another group in the field, gives an idea of magnitude of the currently practical achievable yield.

However, to obtain an overall sustainable solution, other factors are needed to be taken into consideration beyond the yield. “To scale up the water harvesting with MOFs, they should be cheaply accessible in large quantities. Besides, traditional synthesis routes require large amounts of organic solvents or the acquisition of expensive building blocks”, Kaskel and Attallah point to possible pitfalls in this endeavor. To avoid them, recently developed, so-called “ green” synthesis procedures will gain momentum in the future, ensuring eco-friendly production of MOFs. The team from Dresden is already adhering to this idea by following green chemistry´s principles, such as using water as a solvent, running reactions at energy-saving low temperatures, and tapping waste materials as sources of metals and organic linkers.

The study was supported by DFG (Deutsche Forschungsgemeinschaft) under contract 464857745 (AT 289/1-1 and KA1698/41-1).

Original publication:

A.G. Attallah, V. Bon, K. Maity, E. Hirschmann, M. Butterling, A. Wagner, S. Kaskel: “Unravelling the Water Adsorption Mechanism in Hierarchical MOFs: Insights from In Situ Positron Annihilation Lifetime Studies”, in ACS Applied Materials & Interfaces, (2023). DOI: 10.1021/acsami.3c10974

More information:

Prof. Stefan Kaskel

Chair of Inorganic Chemistry

Dresden University of Technology

Tel. +49 351 463 4567

Dr. Ahmed Gamal Attallah Elsherif

Institute of Radiation Physics

HZDR

Tel.: +49 351 260 2323

Media contact:

Simon Schmitt

Head of Communications and Media Relations at HZDR

Tel: +49 351 260 3400

Mob.: +49 175 874 2865

Nicole Gierig

Public Relations School of Science

Dresden University of Technology

Phone: +49 351 463 39 504