C3-V4.6: Energiespeichernder Carbonbeton

Inhaltsverzeichnis

Projektdaten

|

Titel | Title |

Bericht aus dem Jahrbuch 2020

HIN ZU EINER ENTSTEHENDEN ZUKUNFT

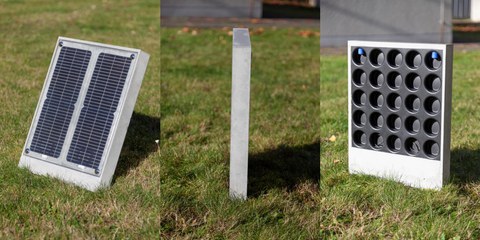

Ausschnitt eines Fassadenelements: Ein 5 cm dickes Bauteil vereint tragende Struktur, Photovoltaik, Kapillarsystem sowie Hohlräume zur Integration von elektrischen Speichern.

Damit technologischer Fortschritt nicht richtungsblind verläuft, ist es zumeist ratsam Neuentwicklungen aus einer erstrebenswerten oder zumindest sich abzeichnenden Zukunft her zu denken. Auch wenn Ansätze individuell und verschieden sind, wird ein Großteil der Entwickler durch das Streben nach nachhaltigen Lösungen für unsere derzeitigen ökologischen und sozialen Herausforderungen geeint. Für das Bauwesen kann daraus das Entwicklungsziel abgeleitet werden, die Aufgaben eines Gebäudes – vom Schutz vor äußeren Einwirkungen bis hin zum Versorgen mit (Wärme-)Energie – mit einem möglichst geringen ökonomischen und ökologischen Aufwand während des gesamten Lebenszyklus zu erreichen. Im Rahmen des vorliegenden Projektes C3-V4.6 Enerton wird der Versuch unternommen, die momentanen Forschungs- und Entwicklungstrends hin zu hohen Automatisierungs- bzw. Vorfertigungsgraden, zu einer steigenden Adaptionsrate von Erneuerbare-Energie-Technologien und zu einer möglichst ressourcenschonenden Bauweise mithilfe von Carbonbeton zu vereinen. Dabei ist das Ziel, den Ressourcenbedarf von Gebäuden sowohl zur Errichtung als auch in deren Nutzungsphase zu minimieren.Mittels experimenteller und numerischer Untersuchungen wurden am IMB Herstell- undKonstruktionskonzepte entwickelt und optimiert, welche das einfache Einbetten von Erneuerbare- Energie-Technologien in den Prozess der Fertigteilherstellung ermöglichen. Ein besonderer Fokus galt der Speicherung von elektrischer Energie sowie der Kabelführung. Der Projektpartner Technische Chemie 1 der TU Darmstadt entwickelte in diesem Kontext temperaturunempfindliche und kostengünstige Stromspeicher mit hoher Zyklenstabilität auf Basis nicht kritikaler Materialien. Die Konzepte wurden auf ihr Biege- und Querkrafttragverhalten untersucht. Wesentliche ökonomische und ökologische Einflussfaktoren wurden definiert und quantifiziert. Für den konkreten Anwendungsfall „vorgehängte hinterlüftete Fassade“ wurden Verbindungselemente auf deren Eignung untersucht. Bezüglich Tragverhalten, Austauschbarkeit und dem zur Verfügung gestellten Volumen zur Funktionsintegration stellten sich dünne Textilbetonplatten mit eingebauten Kassetten als besonders vorteilhaft heraus. Mithilfe von Großbauteil- sowie Brand-versuchen soll die Umsetzbarkeit der entwickelten und patentierten Konstruktions- und Herstellungsmethode vertiefend untersucht werden.

Bericht aus dem Jahrbuch 2019

ENERGIEGELADENE FERTIGTEILE

Schrägzugversuch zur Untersuchung von Verbindungselementen für funktionalisierte Bauelemente

Der Einsatz von erneuerbaren Energien schont die Umwelt. Um die Adaptionsrate erneuerbarer Energietechnologien zu steigern, müssen für die Nutzer wirtschaftliche Vorteile geschaffen werden und der Planungs- sowie Investitionsaufwand verringert werden. Ein Ansatz, der dies ermöglichen soll, ist die Integration erneuerbarer Energietechnologien in den Prozess der Fertigteilherstellung.

Ein wichtiger Teil des Energiesystems sind dabei elektrische Speicher. Innerhalb dieses Forschungsprojektes werden Ansätze entwickelt, um energiespeichernde Materialien in Bauprodukte zu integrieren.

Das Institut für Massivbau beschäftigt sich vorwiegend mit der Entwicklung einer geeigneten Bauteilkonstruktion. Die besondere Herausforderung: Die Energiespeicher müssen derart in das Bauteil integriert werden, dass sie i) die Tragfähigkeit des Bauteils möglichst wenig beeinflussen, ii) ökonomisch sinnvoll gefertigt werden können und iii) deren Funktionsfähigkeit nicht beeinflusst wird.

Dafür wurden zunächst drei Varianten konzipiert und untersucht. Variante 1 sieht die unmittelbare Nutzung der textilen Bewehrung als Elektrode vor; Elektrolyttaschen werden dafür in das Textil integriert. Diese Variante besitzt eine geringe Speicherkapazität und reduziert die Tragfähigkeit des Bauteils maßgeblich.

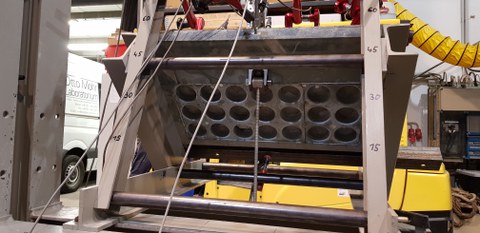

Bauteil mit Hohlräumen zur Funktionsintegration im Versuchsstand

Variante 2 sieht die Integration von Speicherelementen zwischen zwei Textillagen vor. Die Speicherelemente befinden sich in gering belasteten Zonen, wodurch die Tragfähigkeit des Bauteils nur geringfügig beeinflusst wird. Die Speicherkapazität wird im Vergleich zu Variante 1 erhöht. Variante 3 nutzt zur Integration eine Aufnahmestruktur, in welche Speichermodule eingefügt werden. Die Speichermodule sind dabei frei zugänglich und können im Bedarfsfall ausgetauscht werden.

Im weiteren Verlauf des Vorhabens werden das Design des Bauteils, die Leitungsführung sowie die Speichermodule und deren Regelung weiter optimiert. Darüber hinaus werden momentan geeignete Fertigungskonzepte entwickelt und die Skalierbarkeit derartiger bauteilintegrierter Stromspeicher untersucht.

In Zukunft könnten Bauteile dieser Art beispielsweise als Fassadenplatten an bestehende Gebäude oder Neubauten angebracht werden, um so eine Stromversorgung der Bewohner aus erneuerbaren Energien zu ermöglichen.

Bericht aus dem Jahrbuch 2018

ENERGIESPEICHERNDE CARBONBETON-ELEMENTE

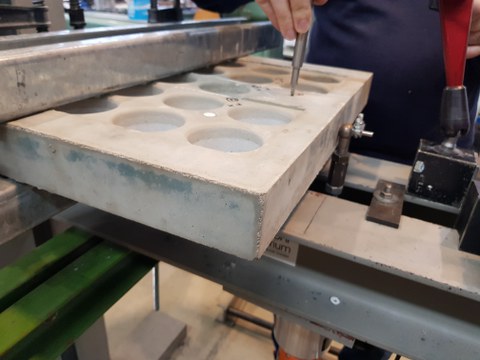

Herstellung eines Betonelements mit integrierter Energiespeicherung

Mit der zunehmenden Umstellung der Energieversorgung auf erneuerbare Energien treten Fragestellungen auf, die bei herkömmlichen Energieträgern wie Kohle oder Erdgas keine große Rolle spielten. Elektrische Energie, welche durch Solar- und Windkraftanlagen gewonnen wird, unterliegt starken zeitlichen Schwankungen. Weiterhin ist der Transport elektrischer Energie über große Entfernungen mit einem großen Aufwand und hohen Verlusten verbunden. Ein „energiespeicherndes Haus“ könnte einen Ausgleich zwischen Energieerzeugung und Verwendung im gesamten Gebäudebetrieb erzielen und eine dezentrale Energieversorgung ermöglichen.

In diesem Kontext werden innerhalb dieses Forschungsvorhabens Ansätze entwickelt, um energiespeichernde Materialien in Bauprodukte zu integrieren. Diese Ansätze sehen vor, die textile Bewehrung unmittelbar als Stromspeicher bzw. -leiter einzusetzen und Beton in gering belasteten Bereichen durch energiespeicherndes Material zu ersetzen. Als wichtige Leitlinien im Vorhaben sollen für die Energiespeicherung bevorzugt einfache, kostengünstige und robuste Verfahren und Materialien verwendet werden. Hier wurden sogenannte Superkondensatoren als besonders vorteilhaft identifiziert.

Zu Beginn des Vorhabens stehen insbesondere die Konzeption verschiedener Konstruk-

tionsvarianten sowie deren Optimierung bezüglich Tragfähigkeit und Speicherleistung im Vordergrund. Eine besondere Herausforderung besteht darin, sowohl die Bauteile als auch deren Teilkomponenten modular und demontierbar zu gestalten, um eine nachträgliche Austauschbarkeit zu ermöglichen.

Biegeversuch eines Betonelements mit integrierten Funktionskörpern

Das Institut für Massivbau ist insbesondere an der Konstruktionsentwicklung sowie der Untersuchung der Tragmechanismen der entwickelten Bauelemente beteiligt. Die Bauelemente aus Carbonbeton sollen – trotz integrierter Energiespeicher – den Anforderungen an Tragfähigkeit und Gebrauchstauglichkeit herkömmlicher Bauprodukte genügen. Einflüsse des integrierten Speichermaterials, insbesondere auf die Biege- und Querkrafttragfähigkeit, werden theoretisch sowie experimentell untersucht. Erste Versuche zeigten bereits, dass trotz integrierter Speichermaterialien eine ausreichende Tragfähigkeit gewährleistet werden kann. Neben den technischen Herausforderungen sind weiterhin Fragestellungen bezüglich des Herstellungsprozesses, spezifischer Anwendungsszenarien sowie einer wirtschaftlich sinnvollen Umsetzung zu beantworten.