Load-bearing behaviour of joints in wind energy plants

Table of contents

Project data

| Titel |Title TP Einfluss von Imperfektionen und Vertikalfugen auf das (Fugen-)Tragverhalten modularer Turmkonstruktionen für Windenergieanlagen im Verbundvorhaben SMARTower: Bemessung und Lebensdauerüberwachung modularer Turmkonstruktionen für Windenergieanlagen | Subproject Influence of imperfections and vertical joints on the (joint) load-bearing behavior of modular tower constructions for wind turbines in the joint research project SMARTower: Design and lifetime monitoring of modular tower constructions for wind turbines Förderer | Funding Bundesministerium für Wirtschaft und Klimaschutz (BMWK) Zeitraum | Period 08/2022 – 07/2025 Verbund- und Teilprojektleiter | Leader of joint research project and subproject Prof. Dr.-Ing. Steffen Marx Team | Team Dipl.-Ing. Florian Fürll, Max Götze M. Sc. Projektpartner | Project partners Institut für Statik und Dynamik, Leibniz Universität Hannover | Institut für Geotechnik, Leibniz Universität Hannover | Testzentrum Tragstrukturen Hannover, Leibniz Universität Hannover | Wölfel Engineering GmbH + Co. KG, Höchberg Assoziierte Partner | Associated partners Max Bögl Bauservice GmbH & Co. KG, Neumarkt | TÜV SÜD Industrie und Service GmbH, München | ENERCON GmbH, Aurich |

Report from year book 2023

Ground but still uneven: concrete rings for wind turbines

3D scan of a model segment

In recent years, so-called hybrid towers have become more and more common, especially for wind turbines with a high hub height. The upper part of such towers is made up of several steel sections, while the lower part consists of precast concrete rings. The individual concrete segments are typically not glued or mortared together, but stacked dry on top of each other and connected by external tendons running inside the tower. Due to the dry joints between the segments, the load-bearing behavior of the tower structure can be significantly influenced by unevenness on the segment surfaces. To avoid major unevenness, the segments are ground during production using a CNC-controlled grinding machine. However, despite the grinding process, ideal evenness of the segment surfaces cannot be guaranteed.

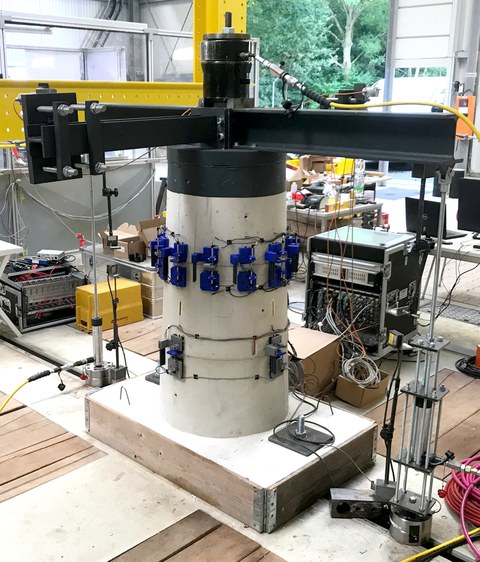

In the SMARTower research project, we investigate the effect of imperfections on the load-bearing behavior of segmented concrete towers with dry joints. To achieve this, large-scale tower tests are conducted using model segments at a scale of 1 : 10. To determine the exact surface geometries of the model segments, a high-resolution scan was performed. The scan revealed that the segments have an elliptical cross-sectional shape as well as imperfections on the grinding surfaces. These unevennesses on the grinding surfaces occur in the form of radial inclinations and circumferential waviness with height differences of a few tenths of a millimeter. Numerical simulations show that, despite their small size, these unevennesses have a significant effect on the stress distribution in the segment joints. In order to confirm this experimentally, tests are currently being carried out on a tower structure consisting of three stacked segments under pure prestressing load. The number of segment levels and the complexity of the loads will be gradually increased in future tests to accurately represent the stress conditions of real hybrid towers.

Report from year book 2022

Concrete towers for wind turbines

Preliminary tests on a tower structure consisting of three stacked reinforced concrete circular ring segments

Wind turbines already account for the largest share of electricity generation from renewable energies in Germany. However, in order to achieve the expansion targets in the field of renewable energies, a further reduction in the costs of wind power generation in terms of production and operation is inevitable. In this context, a large part of the costs is attributable to the tower structure. The production of economical tower structures is associated with increasing hub heights and often larger rotor diameters. This development leads to greater loads, so that significantly higher static and dynamic stresses will be expected in the next tower generations.

The so-called hybrid towers have become established, especially for large hub heights. With the new modular tower generation, additional vertical joints break down the concrete segments into smaller components, so that half, third or quarter shells make a significant contribution to reducing transport costs and assembly effort compared to other concepts. However, the division of the tower construction into individual precast concrete segments leads to a complex load-bearing behavior that is neither fully understood nor can it be reliably modelled so far. The research project SMARTower deals with the load-bearing behavior of such segmented tower constructions under combined loading of prestressing, bending, shear force and torsion. For this purpose, both large-scale tests on model towers on a scale of about 1:10 and detailed investigations on smaller tower sections will be carried out. The aim of the investigations is to determine and evaluate the influence of imperfections and vertical joints on the global load-bearing behavior of the tower construction and the load-bearing capacity of the horizontal joints. Based on the results, realistic engineering design approaches for joint load-bearing capacity are to be developed and validated.

The tests on the model towers are currently under planning. In preparation of the tests a high-resolution 3D scan is to be carried out in order to determine the shape accuracy and flatness of the model segments. With the help of the 3D scan data, an assessment of the influence of imperfections on the load-bearing behavior will be possible after the tests.

Short description

Experimental investigations on large-scale wind turbine tower structures

Wind turbines already account for the largest share of electricity generation from renewable energies in Germany. However, in order to achieve the expansion targets in the field of renewable energies, a further reduction in the costs of wind power generation in terms of production and operation is inevitable. In this context, a large part of the costs is attributable to the tower structure and the foundation. The manufacture of economical tower structures is associated with increasing hub heights and often larger rotor diameters. Significantly higher static and dynamic stresses are therefore to be expected in the next tower generations. To reduce transportation costs and assembly effort, the new modular tower generation uses additional vertical joints to form half, third or quarter shells. However, this decomposition of the tower structure into individual precast concrete segments, between which the transmission of forces takes place exclusively via friction, leads to a complex load-bearing behavior that is neither fully understood nor can be reliably modeled to date. In the research project applied for here, the (joint) load-bearing behavior of such segmented tower structures under combined loading from prestressing, bending, shear and torsion is to be investigated. For this purpose, both large-scale tests on model towers at a scale of about 1 : 10 and detailed investigations on smaller tower sections will be carried out. The aim of the investigations is to record and evaluate the influence of imperfections and vertical joints on the global load-bearing behavior of the tower structure and the load-bearing capacity of the horizontal joints. Based on the test results and numerical accompanying simulations, realistic engineering design approaches for the joint load-bearing capacity are then to be developed and validated. Finally, these design approaches will lead to application recommendations for practice.