DEEPLIGHT

| Funding: |

Bundesministerium für Wirtschaft und Klimaschutz (BMWK) Geothermica & JPP Smart Energy Systems |

| Funding code: | 03EE4042A |

| Partner: |

Netherlands Organisation for Applied Scientific Research TNO IHC Mining B.V. Eindhoven University of Technology Well Engineering Partners B.V. ÍSOR - Iceland Geo Survey Iceland Drilling Company Zorlu Enerji Elektrik Üretím A.S. Lawrence Berkeley National Laboratory Oklahoma State University Werk für industrielle Elektronik BITSz Electronics GmbH |

| Duration: | 11/2022 - 10/2025 |

| Contact: | Erik Neumann |

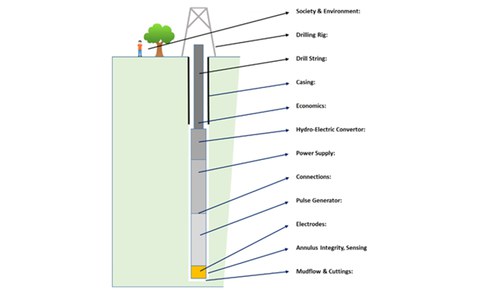

In regard to the energy transition, the use of geothermal energy reserves is a technically attractive but so far little used option for the environmentally friendly provision of energy. In addition, this form of renewable energy is base-load capable and only exposed to minor natural fluctuations. A distinction is made between near-surface geothermal energy and deep geothermal energy, from which the two forms of use of heat generation and the conversion of geothermal heat into electricity are derived. The usability of this geothermal heat varies greatly from region to region and is limited by the depth at which a production well can be operated economically. The costs for drilling this kind of well amount to several million euros and represent a large share of the upfront investment in the overall plant. This financial obstacle is one reason for geothermal energy's low share of 0.3 % of global installed capacity through electricity (in 2021). Deep boreholes usually require hard rock to be drilled. For this purpose, PCD bits are used in conventional rotaty drilling, which are subject to high mechanical wear. The resulting costs concern the drilling tool on the one hand, and the downtime of the rig during tool changes on the other. In order to meet these challenges and make geothermal energy more accessible, an EPP-based (electro pulse power) casing-while-drilling drilling method is being developed with the project partners as part of DEEPLIGHT. This involves a new holistic approach to the drilling process, the drilling tool, the connection of the production well to the geothermal reservoir and the integration of the mentioned points into the existing technical and natural environment. In this process, drilling is not done mechanically, but is implemented by fragmenting the rock with high-voltage pulses. The specific development priorities are summarised in the figure.

Development focus DEEPLIGHT

At the Chair of Construction Machinery, the (co-)development of components of the deep drilling rig is being implemented as part of the project. These include the surge voltage generator, the working electrodes and the converter from hydraulic to electrical energy. Furthermore, the sealing system and the housing of the deep drilling tool are being developed at the Chair of Construction Machinery.