Growth centre LEANTEC drive

| Funding: | Entrepreneurial Regions - innovative regional growth cores Ministry of Education and Research |

| Funding code: |

03WKBY01D 03WKBY03D |

| Partner: | BITz engineering GmbH; KI Keramik-Institut GmbH; RAKO GmbH; SAMAG Saalfelder Werkzeugmaschinen GmbH; Schmuhl FVT GmbH & Co. KG; TU Dresden – Professur für Elektrische Maschinen und Antriebe; TU Ilmenau – Fachgebiet Kunststofftechnik |

| Duration: | 03/2011 - 02/2014 |

| Contact: | Christian Stentzel |

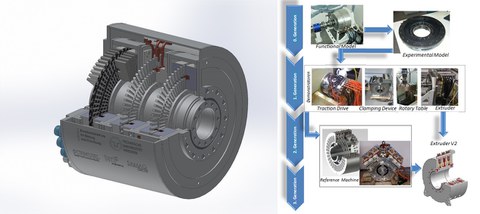

The LEANTEC drive was promoted as part of a growth core (Federal Ministry of Education and Research: “Entrepreneurial Regions”). The consortium consisted of five companies and three research institutions. The aim of the project was the development and the prototype application of a switched transverse flux reluctance machine (TFRM) in a disc rotor design. A "Soft Magnetic Composite" (SMC) was used as the active material, so that permanent magnets and therefore rare earths could be dispensed with. Power densities of approx. 1.4 kW/kg could be achieved depending on a torque-optimized or power density-optimized design. Another advantage is the low copper requirement, since a ring winding energizes several stator poles at the same time and individual stator tooth windings and winding heads are not required. During the development of the LEANTEC drive, attention was paid to consistent lightweight construction. Aluminum alloys and carbon fibre reinforced plastic were used and attention was paid to an axially short construction. A challenge in the development of the LENATEC drive was compliance with the required air gaps between the rotor and stator, which were subject to the restrictions of the manufacturing quality, the electromagnetic forces and the thermal behavior.

Areas of application were tensioning mean and rotary tables of machine tools, as well as a drive for a mobile construction machine and the drive for an extruder screw.