2D and 3D multiaxial warp knitting

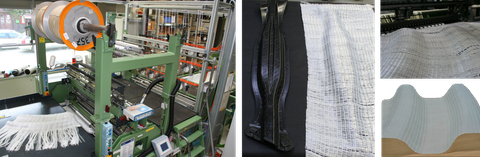

NC-controlled thread feeding and take-off module on a multiaxial warp knitting machine (left) for the production of multiple-curve, textile reinforcement structures with three-dimensional continuous fiber arrangement (right)

In almost all technical fields, fiber-reinforced composites with textile reinforcement structures made from high-performance fiber materials absorbing the tensile forces acting on the component have been firmly established. The reinforcement threads have to be arranged according to the path of the force, and available fabric formation methods have to be suitable to assemble them into matching semi-finished products. A suitable method is presented by multiaxial warp-knitting, whose modularly arranged process steps allow the production of open and closed 2D and 3D structures and other functionalizations depending on the projected use.

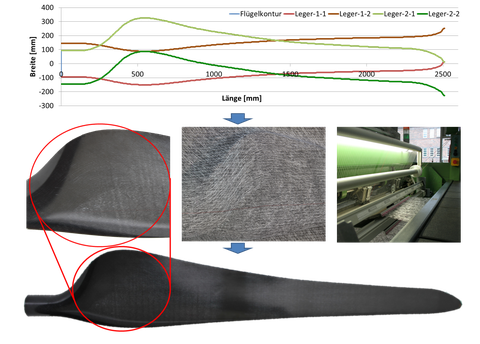

Apart from directly used reinforcement yarns and two-dimensional reinforcement textiles (e.g. bi-directional non-crimp fabrics), textile preforms with a three-dimensional continuous fiber arrangement are becoming more widespread for complex components. These allow the realization of very complex thread courses and a more efficient component production than in a multi-step preform production by means of shaping and joining. The prerequisite are single-step fabric formation processes for an immediate spatial shaping of textile semi-finished products. A new principle, based on warp-knitting technology, for the variable allocation, demand-oriented delivery and subsequent take-off of individual warp yarns of the required length, which allows the creation of plane and spatially curved textile structures with load-adapted reinforcement thread courses, is one such innovative technology. With this, both open and closed near-net shape textile structures with simple curvatures, and freeform surfaces with load-path-adjusted thread courses can be produced.

Warp thread offset technology with CAD-assisted offset generation for efficient and resource-efficient production of load-adapted and / or contour-adapted, continuous-fiber-reinforced semi-finished products on a multiaxial warp-knitting machine

The innovative 2D and 3D textiles are suitable for use in reinforcement components for complex-shape composite materials with mineral or plastic matrices, for reinforcement in wood composite components and for elastomer reinforcement.

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Danny Friese

Leader Multiaxial warp knitting and robotics for composites

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

Breitscheidstr. 78, House D, Room 1.1.13

01237 Dresden