2D and 3D knitting

Flat-knitting machine for the production of near-net shape multilayer flat-knitted fabrics

The development and adaption of textile processes for the direct production of complex-shape 2D and 3D functional structures for various applications has been an important research focus of the ITM for years. Flat knitting in particular shows great potential for the realization of such highly functional, load- and net-shape-adapted textile semi-finished products.

FRPC demonstrator based on near-net shape multilayer flat-knitted fabrics

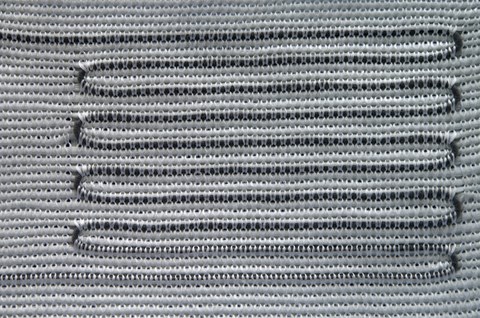

Multilayered knitted fabrics (MLKF) as textile reinforcement semi-finished products for fiber-reinforced plastic composites (FRPC) with stretched reinforcement threads integrated into the mesh structure are a special ITM-made development. Apart from a biaxial (0°, 90°), multiaxial (from 0° to 90°) arrangements of the reinforcement threads in the knitted fabric structure are feasible. Due to the stretched reinforcement thread layers, the MLKF are an excellent choice for the production of heavy-duty FRPC components.

Knitted fabric with integrated sensor threads

One comprehensive aim of the research work is to develop and establish a continuous and automated process chain, which, starting from the 3D CAD component geometry and including simulation-based component design and determination of reinforcement thread arrangement, allows the creation of machine control programs and a direct production of 2D and 3D MLKF preforms.

Compared to the currently established methods for preform production, the MLKF technology offers a variety of advantages:

- near-net shape and near-net geometry production of textile semi-finished products (one-shot technologies)

- minimization of fiber waste (zero waste technologies)

- high degree of functionalization by load-adapted textile semi-finished products by means of local adjustments to the reinforcement effect, and integration of sensors,

- adjustment of impact and delamination properties via the loop thread as reinforcement in z-direction,

- feasibility of textile structure with homogeneous or inhomogeneous reinforcement structures (depending on requirements), and

- processability of high-performance fibers like carbon, glass, basalt or natural fibers, and hybrid yarns in all thread systems.

Further research efforts of the ITM are focused on an adaption of knitting technology to new materials or for the realization of new products, e.g. high-performance sectors like medicine (ortheses, blood vessel replacement), fire protection, geotextiles, architectural textiles, and various multi-material composites.

Knitted orthesis with requirement-adapted, partial reinforcement by means of MLKF technology

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Matthias Overberg

Generative 3D technologies for integration and preforming

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

George-Bähr-Straße 3c, Zeunerbau, Room 111

01069 Dresden