2D and 3D warp knitting

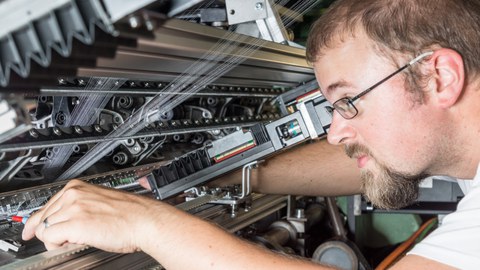

RR raschel machine with an ITM-developed flexible and productive weft insertion system

The warp-knitting method is highly versatile with regard to structure, and very productive, giving it a particularly high potential. However, the highly dynamic thread strains in technical applications require special constructive measures. This includes increases in performance of the warp-knitting machines by means of technological-construction and kinematic modifications, the development of additional systems for warp-knitting machines, and the creation of patterns for warp-knitted fabrics of high complexities. The extension of requirement-adapted technologies and products is always done in co-operation with our industrial partners.

The ITM has made it its task to realize not only CAD-based pattern and structure development of classic and complex technical warp-knitted fabrics , but also machine developments. The thorough analysis of warp-knitting machine with modern measuring technology (highly dynamic tensiometers, 3D high-speed video cameras, accelerometers, and laser triangulators) as well as modal and FFT analyses , allow technological developments for the effective processing of low-elongation threads and the integration of functional threads in warp-knitted fabrics, significantly increasing the performance of the machine and extending the range of function-integrated warp-knitted fabrics in the field of technical textiles. For instance, the ITM has developed solutions for thread tension compensation, allowing high-strength filament, compact and cotton ring yarns to be gently processed on the warp-knitting machine at high RPM numbers.

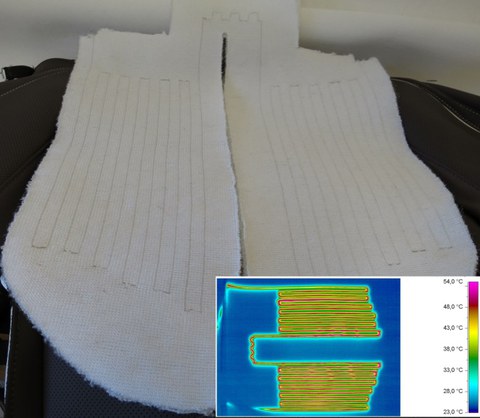

Warp-knitted spacer fabrics with integrated heating wire, and thermal image of the seat heater

To increase product variability and machine performance, a flexible and productive weft insertion system was developed, with which function threads can be integrated directly and variably into the warp-knitted fabrics. By integrating electrically conductive yarns into the warp-knitted fabrics, conventional heater systems like heated car seats, can be produced much faster than today, and innovative heating systems for the area of electromobility become feasible.

Constructive-technological modifications on RR raschel machines allow the effective processing of coarse high-performance threads (carbon and glass fibers from 800 tex) in weft, filler and pile threads. Based on this, warp-knitted spacer fabrics for lightweight panels were developed with closed outer surfaces and reinforcement threads in x-, y-, and z-direction.

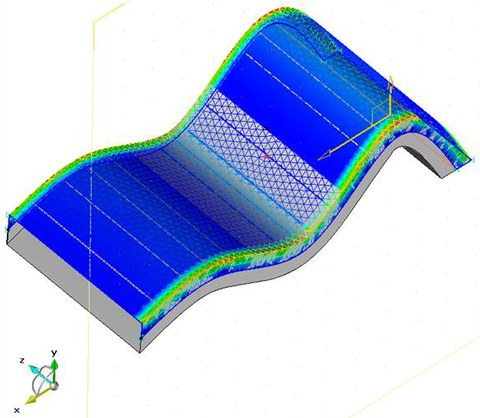

Current development are focused on the realization of variably curved spacer structures with integrated connection elements in various geometries, as large-area lightweight construction panels to be used in automotive engineering, container construction and boat building.

Development of variably curved spacer structures

Modeling the structural behavior of warp-knitted 3D structures

Constructive works at the ITM are accompanied by the modeling and simulation of the thread and machine dynamics, and modeling of the structural behavior of warp-knitted structures by means of the finite element method.

Currently, RL and RR warp-knitting machines are installed at the ITM, which have been fit with completely new modules and allow the production of innovative textile constructions.

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr.-Ing. Danny Friese

Leader Multiaxial warp knitting and robotics for composites

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

Breitscheidstr. 78, House D, Room 1.1.13

01237 Dresden