Fiberbased additive Manufacturing

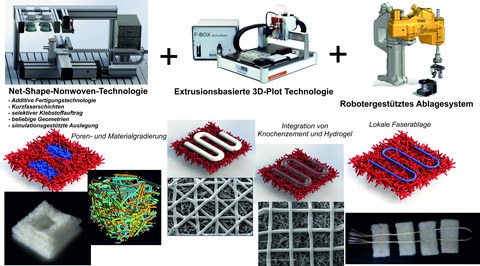

To produce individual and complex implants, an ITM-developed, highly productive, modular, additive production method is used: net shape non-woven technology. This ITM-patented technology enables a layer-by-layer bonding of short fiber layers into complex 3D structures with adjustable porosities. Using different modules for the local placement and defined orientation of short fibers, and for the integration of continuous fibers, the limitations of conventionally produced assembled textiles can be overcome. Furthermore, the process-integrated and extrusion-based 3D plot technology allows the integration of various material types like bone cement, hydrogels, and hollow strings. Thus, the production of customized, requirement-adapted implant structures containing material and structure gradients, anisotropic areas and cavities becomes possible. The simulation-assisted design and the modular, additive production of the structures allows the selection of the necessary components and a specific adaptation of the implant geometry to the individual patient and to complex tissue defects.

NSN technology for the production of individual complex implants

This additive method can be used in a number of additional high-tech applications, where complex geometries are realized without loss of material. This includes ITM-developed preforms for short-fiber-reinforced ceramic composite structures with improved ductility.

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Mr Dr. Michael Wöltje

Research Group Leader Biomaterials and Medical Technology

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

Breitscheidstr. 78, House D, Room 1.1.13

01237 Dresden