Basic research on rods made of recycled carbon fibers

Table of contents

Project data

|

Titel | Title |

Report in the annual report 2023

From recycled filament to the carbon fiber rebar

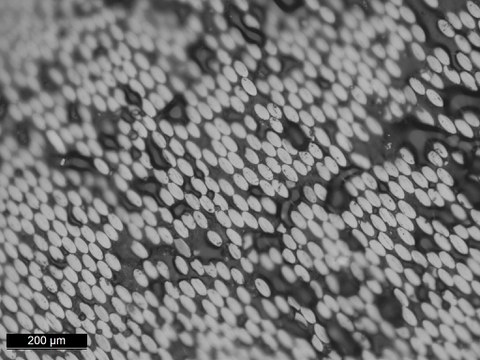

Microscope image of a rebar made from recycled carbon fibers

In the EDISON-rCF project, we conduct extensive experiments with semi-finished products made from recycled carbon fibers, including rods and fabrics. The tests aim to determine the products’ properties, such as tensile strength, bond behavior, and performance at varying temperatures. Fiber orientation, fiber volume content, fiber length, and impregnation material significantly affect the load-bearing behavior.

To investigate the influence of the recycling process (pyrolysis or solvolysis) on the material properties of carbon fibers, virgin fibers were also subjected to pyrolysis or solvolysis. After the recycling process, the tensile strengths of the virgin, pyrolyzed, and solvolysed fibers were determined. Compared to the virgin fibers, a tensile strength loss of around 10 % was observed for recycled fibers.

Afterwards, yarns were spun from the recycled fibers. Two impregnations, based on either a thermoplastic or a thermoset, were utilized to generate the bond within the roving. All yarns analyzed in tensile tests failed at the point where the cross-section was smallest and within the free length between the load introductions. Regardless of the impregnation material used, the tensile strength of the recycled fiber rovings was clearly lower than that of rovings made of virgin fibers. It is crucial to optimize the manufacturing process.

To determine the tensile strength of recycled carbon fiber rods with an outer diameter of 10 mm and 1.20 m length, they were clamped between load introduction plates specifically designed for this purpose and loaded until failure. Two series of five rods were tested. The rebar’s elongation was measured using inductive displacement transducers and photogrammetry. Through the modification of the bar composition from series 1 to series 2 with regard to fiber orientation and fiber volume content, an increase in tensile strength was achieved. The tensile strength of the rods of the second series was roughly 25 % of that of the rods created from new carbon fibers.

Report in the annual report 2022

Reinforcements made from recycled carbon fibers

Cross section of an epoxy resin impregnated yarn made from recycled carbon fibers

Within the EDISON-rCF project, funded by the German Federal Ministry of Economics and Climate Protection (BMWK), the recycling process of carbon fiber reinforced plastics is being investigated from the preparation of recyclable materials to new components. The semi-finished products, like scrims and rods, made from recycled carbon fibers produced in this project will be extensively analyzed in regard to their most important properties, e.g. bond behavior, tensile strength, durability and behavior under different temperatures.

By preparing a working paper, it was possible to establish the requirements demanded of the semi-finished products to be manufactured. In particular, the fiber length and the fiber orientation in the reinforcements are considered to be important properties for the load-bearing behavior.

The impregnation of the carbon fibers is also essential for the manufacturing of bars and fabrics. In order to make an initial statement about the suitability of an impregnating agent, yarns made from recycled carbon fibers were impregnated with polymer, duromer, and geopolymer and investigated for the respective tensile behavior. The yarn impregnated with epoxy resin prevailed due to the highest tensile strength and the highest stiffness. All yarns failed at the point of lowest cross-section and without advance notice. Using the thin section method, it was also possible to assess the impregnation quality.

The profiled carbon fiber rods made from recycled carbon fibers by one of our project partners had an outer diameter of 10 mm and a relative short length of 60 cm due to the current manufacturing process. The bars were embedded in 20 × 20 × 20 cm concrete cubes with 5 cm bond length. In order to be able to make a statement about the bond behavior of the bars, they were loaded to failure in pull-out tests. All bars tested failed before the onset of pull-out. Therefore, in the further course of the project, the increase of the inner bond of the bar is to be advanced.