TP 4: Verbindungen gemäß bautechnischer Anforderungen (TAVIMBA)

Inhaltsverzeichnis

Projektdaten

|

Titel | Title |

Bericht aus dem Jahrbuch 2020

BLINDE VERBINDUNG

Bestimmung der Auszugskraft einer neuartigen Montageschiene

Das Material Carbonbeton ermöglicht die Herstellung dünnwandiger Platten. Weiterhin eignet sich Carbonbeton für eine modulare Bauweise. Um die dünnen, vorgefertigten Bauteile auf der Baustelle zu verbinden, bedarf es neuer Befestigungs-systeme. Drei wesentliche Entwicklungsziele stehen dabei im Vordergrund. Erstens die sichere Kraftübertragung vom Verbin-dungselement in die dünnwandige Platte, zweitens eine einfache Montage und drittens eine möglichst geringe Beein-flussung der Ästhetik durch das Befestigungssystem.

Im Rahmen des Projektes „TAVIMBA“ werden neue Befestigungs-systeme entwickelt, die auf Basis von Formgedächtnislegierungen (FGL) funktionieren. Die FGL wird dabei als aktives Verbindungselement genutzt. Durch thermische oder elektrische Aktivierung dehnt sich diese aus und klemmt sich dabei in eine Montageschiene, wodurch eine kraftschlüssige Verbindung hergestellt wird. Mit dieser Form der Aktivierung kann auf eine mechanische Zugänglichkeit verzichtet werden. Die Verbindung kann somit blind hergestellt werden, die Montagestelle ist von außen nicht sichtbar.

Innerhalb des Projektes wurden unterschiedliche Konzepte zur Umsetzung eines derartigen Befestigungssystems entwickelt und untersucht. Dabei waren zwei Stellen von besonderem Interesse: einerseits die Verbindungsstelle zwischen FGL und Montage-schiene und andererseits die Verbindungsstelle zwischen Montageschiene und dünn-wandiger Platte aus Carbonbeton.

Für die Verbindung zwischen FGL und Schiene wurden durch die Projektpartner numerische und experimentelle Untersuchungen durchgeführt, um den Verbindungs-prozess besser zu verstehen, die beeinflussenden Parameter zu bestimmen und diese zu verbessern. Auf diese Weise gelang es, eine ausreichende Auszugskraft der FGL aus der Montageschiene zu erzeugen. Für die Verbindung der Montageschiene mit der dünnwandigen Platte wurden unterschiedliche Ansätze umgesetzt und experimentell getestet. Dabei zeigte sich, dass eine vollständige Einbettung der Schiene in die Platte prinzipiell möglich ist.

Für den Anwendungsfall „vorgehängte, hinterlüftete Fassade“ sollen im weiteren Verlauf bauteilartige Versuche durchgeführt und ein Demonstrator umgesetzt werden. Zukünftig soll dieser Ansatz auf lösbare Verbindungen übertragen werden, um die Umsetzung einer nachhaltigen modularen Bauweise zu unterstützen. Dies bedarf jedoch weiterer umfangreicher Forschungs- und Entwicklungsschritte.

Bericht aus dem Jahrbuch 2019

BRANCHENÜBERGREIFENDE INNOVATION – CARBONBETON VERBINDET

Rendering eines Torsionsankers aus FGL

In Deutschland besteht momentan ein großer Bedarf an günstigen Bildungs-, Gewerbe- und Wohnbauten. Flexible Bauverfahren und Modularität haben das Potential, diesem Bedarf zu begegnen. Dabei bestehen Teile des Bauwerks – wie etwa die Fassade – aus vorgefertigten Modulen. Diese Einzelmodule werden konventionell mittels Einlegteilen oder Vergussverbindungen miteinander verbunden. Dies setzt eine mechanische Zugänglichkeit der Verbindungsstellen für die Montage bzw. Demontage voraus. Wird die Verbindung mittels Verguss realisiert, so ist ein Lösen überhaupt nicht mehr möglich; ein Wiederverwenden der Bauteile wird somit erschwert.

Im Projekt „Thermisch aktivierte Verbindungen in modularem Bauen (TAVIMB)“ sollen smarte Verbindungen entwickelt werden, welche ohne mechanische Zugänglichkeit verschlossen und ggf. wieder geöffnet werden können. Dafür sollen auf Basis thermische Formgedächtnislegierungen (FGL) Lösungen entwickelt werden, welche mittels thermischer bzw. elektrischer Stimulation geöffnet und ggf. wieder geschlossen werden können. Durch deren nahezu 100 %ige Strukturintegration sollen Verbindungen ermöglicht werden, welche weniger raumintensiv sind und somit auch eine einfache Verbindung dünner Bauteile aus Carbonbeton ermöglichen.

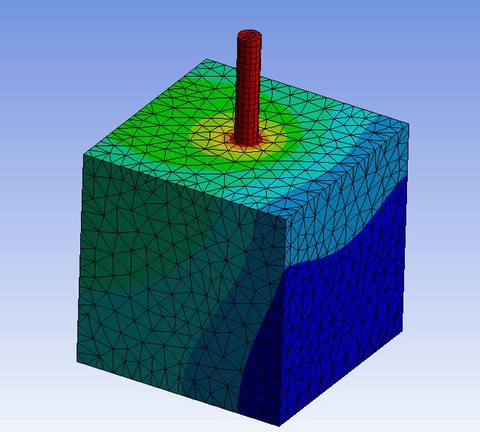

Thermische Analyse bei Aktivierung der FGL

Thermische Formgedächtnislegierungen haben die Fähigkeit, auf Änderungen des thermischen Feldes mit reversiblen mechanischen Änderungen zu reagieren. Im martensitischen Zustand kann ein Element aus FGL scheinbar plastisch (pseudoplastisch) verformt werden. Erhitzt man das Element im Anschluss über seine Umwandlungstemperatur, nimmt es die zuvor eingeprägte Form wieder ein. Mithilfe dieses Effektes sollen Verbindungselemente entwickelt werden, welche auf sichere, schnelle und zuverlässige Weise modulare Bauteile (Fassaden, Betonplatten, Balken, Stützen...) verbinden.

Das Institut für Massivbau beschäftigt sich mit den Grundlagen der Auslegung und unterstützt bei der Entwicklung des Gesamtdesigns der Verbindung. Dieses muss derart gestaltet sein, dass alle bautechnisch relevanten Anforderungen erfüllt werden. Dazu müssen die sicherheitsrelevanten statischen Anforderungen bezüglich der Verbindungselemente auch für eine sichere Lasteinleitung in dünne Bauteile erfüllt werden. Um das Projektziel zu erreichen, sind sowohl theoretische Überlegungen, also das klassische Konstruieren, wie auch praktische Erprobungen und Bestimmen von Bauteilwiderständen, also der Lastkapazität der Verbindung selbst und deren Einbindung in Bauteile, notwendig.