smart_tendon

Table of contents

Project data

| Titel | Title TP der TU Dresden im Verbundprojekt smart_tendon: Erfassung von Bauwerksdaten mittels in Spannglieder integrierter ortsauflösender Dehnungssensoren | Subproject of the TU Dresden within the joint research project smart_tendon: Acquisition of structural data by means of spatially resolved strain sensors integrated in tendons Förderer | Funding Bundesministerium für Digitales und Verkehr (BMDV) Zeitraum | Period 11/2021 – 10/2024 Teilprojektleiter | Subproject manager Prof. Dr.-Ing. Steffen Marx Bearbeiterin | Contributor Dr.-Ing. Kerstin Speck Projektpartner | Project partners Institut für experimentelle Mechanik, HTWK Leipzig | DYWIDAG Systems International GmbH, Leipzig | MKP GmbH, Weimar | Ingenieurgesellschaft für experimentelle Bauwerksuntersuchung mbH, Leipzig | Solifos Deutschland GmbH, Bonn |

Report from year book 2023

smart tendon in research bridge

The smart tendon is passed out of the tendon through a special cap

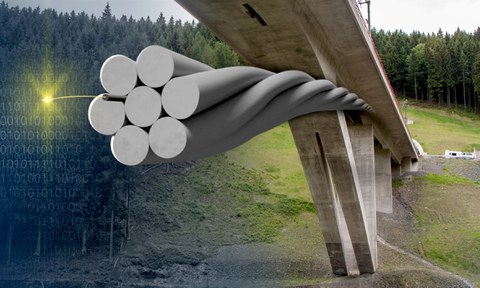

In the case of a smart tendon, fiber optic sensors are integrated directly into prestressing steel strands to continuously measure the strain along them. At the same time as the tendon, a sensor is integrated into prestressed concrete bridges that can record the condition of the bridges over their entire service life. Damage-free structures can thus be inspected in detail as part of the main inspections or the effects of abnormal heavy loads can be documented without significant effort. Above all, however, damage can be detected at an early stage, measured values can be included in a recalculation and the smart tendon can be integrated into a monitoring concept.

The arrangement of the fiber optic sensors in the tendon was developed and optimized by our project partners in Leipzig and Bonn. The suitability of the sensor configuration was demonstrated on small-format test specimens and the areas of application were defined. Possible damages such as breaks of prestressing wires or grouting errors were clearly recognizable in the measured values. The effects of cracks on the stiffness of a component and thus the strain in the tendon, on the other hand, are to be characterized in large-scale laboratory tests. Suitable prestressed concrete beams were designed at our institute.

A smart tendon will be put to practical use in the research bridge that is being built as part of the IDA-KI project. Strands were equipped with fiber optic sensors for this purpose. These strands were used both as post tensioned strand in the tendon and as pretensioned individual strands in a prefabricated element. Numerous constructive challenges were solved. The measuring fiber itself, which runs protected inside the strand in the structural member, leaves the strand at the end of the structural member via the end face of the strand. Solutions were developed for the pre-tensioning process, shortening the strand, creating corrosion protection and, last but not least, the robust and durable connection of the sensor.

Very promising measured values were recorded during a test loading of the prefabricated element before installation in the bridge. As part of the research bridge, the smart tendon will be able to demonstrate its full potential in future and also be tested under exceptional load situations.

Report from year book 2022

smart tendon passes first tests

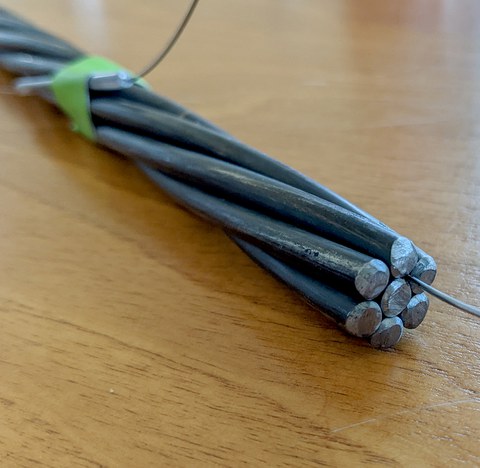

The inside of a smart tendon

To reduce the consumption of resources, infrastructure structures should be used for as long as possible and maintained efficiently. To this end, bridges are regularly inspected and, if damage is detected, recalculated and, if necessary, monitored. The partners in this project are developing sensors for prestressed concrete bridges which, as so-called smart tendons, record the condition of the bridges over their entire service life. The favored fiber-optic sensors are integrated directly into the tendons and enable location-resolved strain measurement along them.

Our project partners in Leipzig and Bonn jointly selected suitable fiber-optic sensors and optimized their properties to suit the planned application. Post-tensioned concrete bridges are mainly using bonded tendons consisting of prestressing seven-wire strands. These strands consist of an outer layer of six parallel wires stranded around a straigth core wire. The sensors were applied to the strands in several ways: they ran outside in the gap between two outer wires following the strand surface, outside parallel along the strand axis crossing all outer wires or inside in the space between the wires. For reference measurements, sensors were also glued into a groove made in the core wire. In all application methods, a good strain transfer between prestressing steel and fiber-optic could be achieved. The tensile test results on single strands were comparable to the results of the additionally installed external displacement sensors. These measurement results were only locally influenced by the increased transversal pressure in the wedge anchorage area.

In parallel, prestressed concrete beams for large-scale laboratory tests are being designed at our institute. The findings of the small-scale tests are integrated into the test concept in the same way as the requirements from bridge monitoring. Thus, the regular service condition, possible damage scenarios and failure conditions are to be simulated in the laboratory. The effects of these conditions on the strains in the smart tendon are to be characterized and detected automatically. If the strain curves characterized in this way are identified in future bridge monitoring, reliable conclusions can be drawn about the condition of the bridge.

Report from year book 2021

Monitoring bridges for life

ensors integrated in tendons for structural monitoring

The BMVI has numerous data in the field of transport, infrastructure, satellite, environmental and weather measurement. The funding programme “Modernity Fund” aims to develop innovative data use and networking options and to identify future data needs and utilisation options. Additional funds are available to support structural change in coal regions. In the programme module “Digitisation and data-based innovations for Mobility 4.0 and services of general interest in the lignite mining regions”, a joint research project was therefore launched under the coordination of the HTWK Leipzig, in which other partners from the Central German coal mining region are involved and companies from the Lusatian mining region are also to be integrated.

The project is focused on prestressed concrete bridges with the aim to ensure that infrastructure structures can be used for as long as possible, maintained efficiently and thus save resources. The condition of the bridges is regularly checked and, if damage is detected, subjected to recalculation and, if necessary, monitoring. The database created in this way could be significantly enhanced and made more detailed through the long-term measurement of deformations inside the bridges. Therefore, sensors are to be developed that can be integrated directly into the tendons and record the condition of the bridges over their entire service life. Fibre optic sensors are favoured, which enable a spatially resolved strain measurement along the tendons. Due to the rigid bond between the tendons and the concrete of the structure, the current condition of the structure can be detected and compared with the design, and any damage to the structure can be detected and localised at an early stage. Various technical approaches are being pursued for the robust and permanent integration of the sensors into the tendons. After the development of suitable protection systems for the sensors and of technologies for integration in the tendon, laboratory tests will be carried out on individual tendons equipped with strain sensors, so-called smart tendons. Later, the smart tendons will be tested in large-scale laboratory tests on prestressed concrete beams and in a real bridge structure. This will be supplemented by the development of monitoring concepts for bridges that include the measured values.