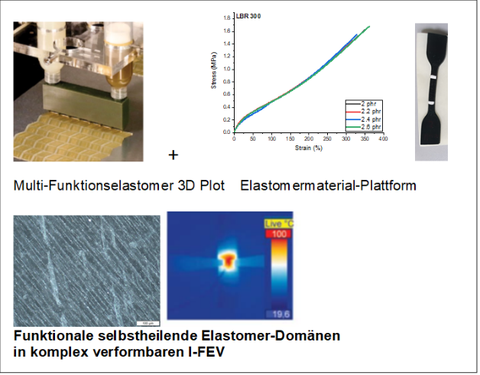

Promotionsprojekt 3: Multi-Funktionselastomer-3D-Plot zur lokal steuerbaren Integration funktionaler Elasto-mer-Domänen in komplex verformbaren I-FEV

Inhaltsverzeichnis

Motivation

Die Umsetzung von I-FEV mit räumlichen Verformungsmustern erfordert die lokal steuerbare Integration funktionaler Elastomer-Domänen in komplex gestaltete gradierte 3D-Textilstrukturen. Dafür müssen neue generative Fertigungskonzepte für Verbundbildung und –konsolidierung erschlossen werden, die eine simultane Preformerzeugung und Formstabilisierung der Elastomerkomponente durch präzise initiierte Netzwerkbildung mittels lokalen Energieeintrags sicherstellen. Um die Lebensdauer der Elastomerkomponenten im I-FEV zu erhöhen, können Selbstheilungseffekte mittels alternativer Vernetzungskonzepte implementiert werden. Dafür müssen die Verarbeitungseigenschaften der Elastomer-Werkstoffbasis an die Anforderungen des Multifunktionselastomer-3D-Plots adaptiert werden.

Stand der Forschung und eigene Vorarbeiten

Der Multimaterial-3D-Druck hochdeformierbarer Polymerstrukturen zur Realisierung pneumatisch aktuierter Soft-Robotics Walkern, Matrix-integrierten Sensorstrukturen oder für die lokale Implementierung aktuierbarer ferromagnetischer Elastomerdomänen ist aktuell Gegenstand intensiver Forschung [1-3]. Dabei kommen die etablierten Materialbibliotheken und Vernetzungskonzepte für Polydimethylsiloxan- und Polyurethan-Elastomere zum Einsatz, wobei die Kombination mit funktionalen oder verstärkenden Textilstrukturen bisher nicht erforscht wurde. In der 1. Kohorte wurde eine auf druckbaren Dien-Flüssigkautschuken basierende Elastomer-Plattform entwickelt, umfassend charakterisiert und deren Eignung als Matrix für ebene hochdeformierbare FGL (Formgedächtnislegierung)-aktuierte I-FEV nachgewiesen. Durch Additivierung mit Partikelsystemen konnten auch funktionale, piezoresistive und magneto-sensitive Flüssigkautschuk-Elastomere mit definierter Deformationscharakteristik erzeugt werden. Die durch intrinsische Erwärmung aktivierbare Selbstheilung von ionisch vernetzten Elastomeren wurde in Vorarbeiten des Antragstellers und Mitarbeitern nachgewiesen und untersucht [4,5] und soll auf die funktionellen Elastomerkomponenten in I-FEVs übertragen werden. Somit besteht ein hoher Forschungsbedarf bzgl. der 3D-Fertigung von Dienkautschuk-basierten funktionalen Elastomerdomänen und deren Integration in räumlich verformbare Verbundstrukturen.

Wissenschaftliche Fragestellung und Projektziele

Das Hauptziel des PP 3 in der 2. Kohorte ist die Konzeption und Erforschung einer generativen Technologie für die lokal auf der Mesoebene steuerbare, definierte Anordnung multifunktionaler hochviskoser Elastomer-Präkursordomänen in hierarchisch strukturierten 3D-Textilstrukturen und deren prozesszeitadäquate in situ Netzwerkbildung in einem generativen Bauprozess des I-FEV. Dafür müssen auf die spezifischen Vernetzungsmechanismen abgestimmte lokal und temporär steuerbare Energieeintragsmechanismen (z. B. fokussierte IR-LED-Strahler) erforscht und technologisch umgesetzt werden. Als funktionelle Elastomere sollen für die Realisierung definierter 3D-Verformungen mit hoher Schaltfrequenzen (>10 Hz) elektroaktive & dielektrische Elastomere im Vordergrund stehen, wobei durch alternative Vernetzungskonzepte auch die Implementierung von Selbstheilungseffekten zur Lebensdauererhöhung der elastomeren Funktionskomponente betrachtet werden [6].

Literatur

| [1] |

J. Herzberger et al.: Polymer Design for 3D Printing Elastomers: Recent Advances in Structure, Properties, and Printing. Progress in Polymer Science 97(2019)101144 |

| [2] | J.J. Schwartz, A.J. Boydston: Multimaterial actinic spatial control 3D and 4D printing. Na-ture Communications (2019)10: 791 |

| [3] | X. Zhao et al. Printing ferromagnetic domains for untethered fast-transforming soft materi-als. Nature Vol. 558 (2018) 274 |

| [4] | H.H. Le et al. Triggering the self-healing properties of modified bromobutyl rubber by intrinsically electrical heating. Macromolecular Materials & Engineering 302 (2016) 1600385 |

| [5] | A. D. Sarma et al. Determination of phase specific localization of carbon black in ternary rubber blends: A macroscopic approach by fourier transform infrared spectroscopy (FTIR). Polymer 150 (2018) 64 |

| [6] | L. Duan et al. A dielectric elastomer actuator that can self-heal integrally. ACS Applied Material and Interfaces 12 (2020) 44137 |

Kontakt

Institut für Werkstoffwissenschaft (IfWW), Professur für Elastomere Werkstoffe, Fakultät Maschinenwesen der TU Dresden

Leibniz-Institut für Polymerforschung Dresden e.V. (IPF)

© Christian Hüller

© Christian Hüller

Herr Prof. Dr.-Ing. Sven Wießner

Forschungsbereichsleiter "Elastomere"

Besucheranschrift:

Leibniz-Institut für Polymerforschung Dresden e.V. Hohe Straße 6

01069 Dresden

Deutschland