2D and 3D weaving

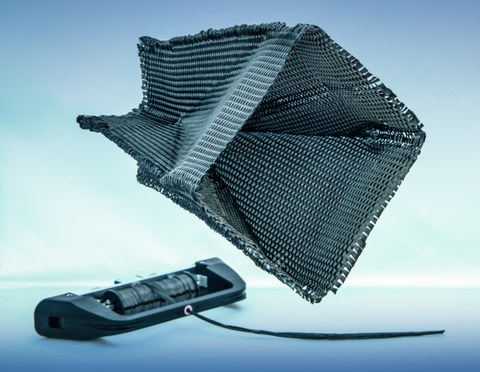

Development of 3D woven wire fabric

One special research competence of the ITM is dimensioning, developing and producing 2D and 3D woven fabrics with customized properties. This consists of the technological-construction enhancement of weaving machines for the processing of different high-performance fiber materials (standard yarns, tape materials, aramid, glass, carbon, ceramics, and wires) into complex, load-adapted woven fabrics in integrated designs.

The important focus is placed on the development of a continuous, simulation-assisted engineering, from the computer-aided design to the integrally woven 2D and 3D preform. Extensive experience has been gained in the area of weave pattern development for spatial construction in complex designs. 3D woven fabrics at the ITM includes multilayer and spacer fabrics, as well as fabrics in fully spatial 3D designs. A team of highly-qualified scientists and technicians work with a range of modern weaving machines and accessories to master a variety of challenges in fabric development and to realize complex net-shape structures.

The ITM has gained expert knowledge in the fields of high-density woven fabrics, twistless processing of tape yarns, low-damage processing of carbon heavy tows (up to 2 x 50 K) into non-crimp grid woven fabrics, the production of non-crimp multilayer woven fabrics (up to 8 kg/m² area mass) and of spacer/shell-rib woven fabrics. The institute’s excellent work in original fabric development has been acknowledged with prizes by the panels of the JEC Paris and Techtextil expert shows, the AVK Innovation Award and a number of other highly renowned international honors.

Profile ribbon fabrics

Based on the new shuttle weaving technology, carbon yarns can be processed with little to no damage, and profile ribbon fabrics with diameters changing along the component length are as easily feasible as complex, tubular node elements woven in a single production step. With the development of wire spacer fabrics and the corresponding conversion of a weaving machine, the groundwork was laid for an entire new cellular type of wire structure for hybrid materials and metal-based lightweight construction. Fabric testing and assessment of geometrical, textile-physical and composite parameters is part of the ITM portfolio and rounds out the institute’s abilities for the development of woven technical textiles.

ITM-made 3D woven node elements

Weaving machines with automated Jacquard technology in all variations (ribbon/tape weaving, weaving, spacer weaving, profile weaving) are available at ITM and allow the simulation-assisted realization of all possible kinds fabric constructions.

Rapier weaving machine DORNIER P1 for the production of multilayer woven fabrics

Contact person:

© Mirko Krziwon

© Mirko Krziwon

Ms Dr.-Ing. Cornelia Sennewald

Managing Senior Assistant

Send encrypted email via the SecureMail portal (for TUD external users only).

Visitor Address:

Hohe Straße 6, Room 143

01069 Dresden

Deutschland