ConPrint3D

ConPrint3D - Ultralight

| Funding: | Research initiative "Future Building" of the Federal Institute for Research on Building, Urban Affairs and Spatial Development |

| Funding code: | SWD-10.08.18.7-17.07 |

| Partner: | Institut für Baubetriebswesen (TU Dresden), Institut für Baustoffe (TU Dresden) , KNIELE GmbH, Opterra GmbH, BAM Deutschland AG, MC-Bauchemie Müller GmbH & Co. KG |

| Duration: | 06/2017 - 06/2019 |

| Contact: | Mathias Näther |

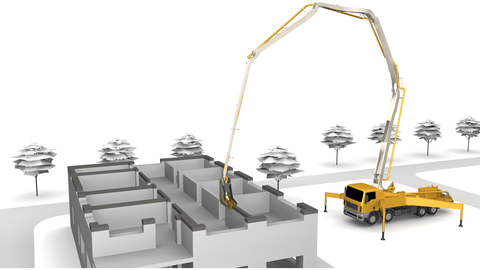

The structural and machine-technical requirements for an additive construction process with foam concrete are created in the research project. Light, load-bearing building walls with low heat transfer have so far been manufactured discontinuously by hand from masonry (perforated brick, aerated concrete blocks). The automatic, formwork-free formation of pumpable foam concrete is intended to revolutionize the manufacture of such structures. Buildings can be continuously manufactured with significantly less personnel and low costs with the help of printed foam concrete. The need to apply additional heat-insulating layers is eliminated. This greatly simplifies and speeds up the construction process and subsequent recycling.