Study Process Engineering and Natural Materials Technology

Table of contents

Process Engineering and Natural Materials Technology at TU Dresden - Topics and Future Prospects

Process engineering enables the industrial conversion ofCO2 into synthetic fuels, milk into curd or molasses into biodegradable plastics. It plays an important role in almost all areas of our everyday lives, be it in the production of food, textiles, medicines or in the increasingly important production of energy from renewable raw materials. Process engineering is an engineering science for all-rounders that deals with the physical, chemical and biological conversion of materials in industrial processes. Natural materials technology focuses on the use of renewable resources such as wood, plant fibers or microorganisms.

In both process engineering and natural materials technology, the focus is on technical

processes in which a new product is created from a raw material. Like all areas of our daily lives, process engineering is also subject to ever-increasing digitalization. This development is taken into account in the training content through the increased teaching of knowledge in the computer-aided design and simulation of industrial processes.

Graduates of the Process Engineering and Natural Materials Technology degree program at TU Dresden have a wide range of employment opportunities in research and all areas of industry thanks to their sound engineering education. They develop industrial processes for material conversion, design production plants and monitor their operation. They are involved in the development of new products from natural substances and take on tasks in the areas of management and quality assurance. The future well-being of our society can only be ensured through sustainable industrial management. Our graduates make a decisive contribution to this by developing resource-saving, highly efficient industrial processes and products based on renewable raw materials.

Process engineers find employment here, for example:

- Chemical industry

- pharmaceutical industry

- Cosmetics industry

- Food and luxury food industry

- Plastics and rubber industry

- Wood, paper, paint and varnish industry

- Environmental technology

- Energy technology

- Plant and apparatus engineering

- Automotive industry

- Medical technology

- Research and development

Portrait of graduate Johannes Boenke (class of 2022)

1. What position do you hold and what does your day-to-day work look like?

As an engineer at the Dresden-based plant engineering company Sunfire, I am involved in the pre-development of electrolysers for hydrogen production. The activities are varied and cover theoretical and practical tasks. One day I work on new control concepts or carry out process engineering calculations. On other days, I work on one of our test benches to check the theoretical preliminary considerations. And on another day, I accompany a commissioning and proudly see how my ideas from pre-development have been implemented in a functioning production plant.

2. What fascinates you about your work?

I am fascinated by the fact that solving technical challenges always works best in a team. We discuss possible solutions with our colleagues. In order to implement the best suggestions, you have to deal with other internal departments, e.g. production or those responsible for the test stand. If a solution can be successfully developed in the end, it is a good feeling. Above all, there is always the fascination of being able to work on one of the key technologies of the future with hydrogen production.

3. Which experiences from your studies in Process Engineering and Natural Materials Technology have benefited you the most in your career?

The practical work for the internship and the diploma thesis had a great impact on me, as you are prepared for solving problems from industry. In the exercises accompanying the lectures, all the necessary quantities for calculation tasks are known. In the practical course, you learn to find the required variables yourself or to make plausible assumptions in order to be able to complete a successful calculation at the end. You also get to know processes in companies and find out whether the industry interests you.

4. Did you have a specific career goal during your studies? How did your career develop in comparison?

After leaving school, I didn't know where I wanted to go. In the mechanical engineering-based foundation course, I was particularly interested in the automotive industry and saw my future there. However, I discovered my love for process engineering through the lectures in my main degree course and my specialist internship at IBU-tec Weimar. Against the backdrop of the major challenge of a decarbonizing economy, I completed a research internship and thesis in the hydrogen industry, which still holds me in its spell. Looking back, it was not a straightforward path, but one from which I was able to take away many different experiences.

5. What advice would you give to students starting out in their careers?

Just go for it. You gather a lot of new impressions in the first few months. You may be the newbie, but use this as an opportunity to ask questions and try things out. Don't wear yourself down by being too ambitious - you still have a whole working life ahead of you.

And most importantly: keep in touch with your fellow students. The friendships you make and get-togethers are worth even more, especially after graduation.

The education and research program of the Dresden Process and Natural Products Engineering is supported by the following professorships & working groups

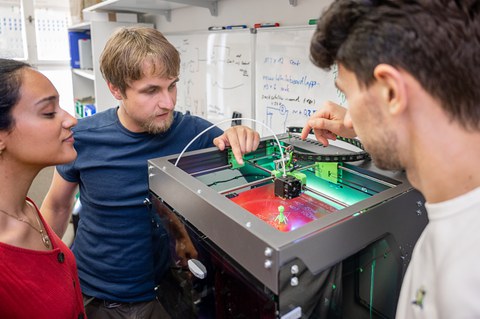

Our expertise ranges from using natural substances to produce sustainable products and foodstuffs to classic topics in (bio)chemicals. But also from mechanical process engineering to modern information technologies to digitalize production processes. By working on our research topics, students have the opportunity to gain practical experience at an early stage and come into contact with socially and technically highly relevant topics.

Basic studies (1. - 4. semester)

In the first four semesters, students are taught primarily mathematical-scientific and engineering fundamentals and general basics of process engineering and natural materials technology. Compulsory modules include the basics of process engineering and natural materials technology, mathematics, chemistry, measurement and automation technology, computer science, and business administration.

Major studies

In the second part of the study course the basic training is combined with application-oriented knowledge transfer. Students can choose one of five fields of study. The respective compulsory program in the 5th to 9th semesters (diploma)/ 5th semester (bachelor's degree) is supplemented by modules. Students can freely select from a catalog of subjects according to their specialist interests. Specialized and research internships in the diploma program and modules for general and interdisciplinary qualifications, for example, subjects from the humanities or economics, round off the range of courses. The following fields of study are available for selection from the 5th semester onwards:

Food engineering - synonymous with food technology - deals with all processing and procedural operations used to transform agricultural raw materials into edible and safe foods sustainably. This requires engineers with sound scientific and engineering skills who are familiar with the specific properties of the raw materials, the intermediate products and the foodstuffs at the end of the value chain when planning, implementing and monitoring the necessary procedures and processes, as well as taking into account the special features of food process engineering.

In addition to general process engineering content, students are taught specific knowledge of food chemistry, food microbiology and hygiene, and the processes and procedures required for food production and their technical implementation. According to personal interests and preferences, students can also specialize through individual module selection, e.g., in biochemistry and nutritional physiology, quality assurance and food sensory analysis, food rheology, plant and safety engineering, beverage technology and food additives, as well as cleaning technology, industrial hygiene, and food packaging.

The field of study is particularly suitable for students looking for a combination of scientific and technical content with strong relevance to everyday life. Graduates of food technology are employed primarily in food-producing companies, where they take on a wide variety of tasks, for example, in research and development, process and product development, as well as in production monitoring, and quality management.

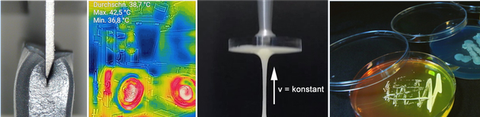

Process technology is an interdisciplinary engineering discipline that deals with the industrial conversion of substances or mixtures of substances, such as organic or inorganic raw materials, building materials, foodstuffs, waste materials, water or air. The conversion of substances can take place with the aid of physical (thermal or mechanical), chemical or biological processes.

In general process engineering, the diverse conversion processes are traced back to so-called "basic processes" or "unit operations", the sequence of which represents a process from the raw material to the end product. These basic processes are initially considered and researched separately from the products.

On the basis of solid scientific and technical knowledge, General Process Engineering investigates in particular the microprocesses of material conversion, which can be used, for example, for the separation of very fine particles on and in filters, the drying of moist wood chips, the extraction of flavors from solids, the grinding of cereal grains, the mixing of color pigments into polymer materials, or the classification of abrasive particles according to their size. These micro processes are realized in technical apparatus or machines (stirred tanks, mills, distillation columns ). Process engineers learn to dimension these apparatuses, to operate them in a resource-efficient manner, to monitor them metrologically, to interconnect them in plants and to control them automatically.

An essential method of general process engineering is to abstract the respective concrete application in order to be able to transfer the developed model concepts to as many applications as possible. From the point of view of process engineers, there is no significant difference between shredding construction waste and grinding roasted coffee beans. The same applies to the distillative separation of petroleum into tar, fuel oils, light gasoline, etc. and the distillation of mash to produce whisky or bio-ethanol. T

his interdisciplinary approach opens up a wide range of professional fields of application (research, process and product development, production monitoring, plant planning, plant control, quality management) for graduates of general process engineering in many different branches of industry (e.g. pharmaceuticals, cosmetics, pigments, large-scale chemicals, paper technology). In the specialization subjects, they can also acquire special skills in process automation, recycling technology, product development or particle technology, among others.

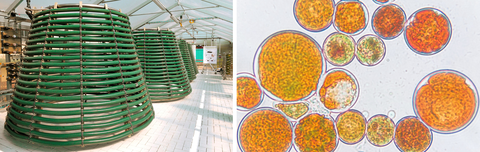

Bioprocess engineering, bioengineering, and industrial biotechnology are synonyms for the scientific discipline that deals with implementing biological material transformations in industrial processes. The focus is on the sustainable production of valuable chemical substances from renewable raw materials or waste streams.

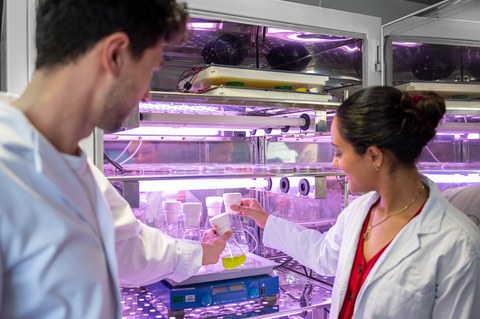

Bioprocess engineering is located at the interface of biology and engineering sciences. In addition to general process engineering content, students are taught the knowledge necessary for developing and optimizing biotechnological manufacturing processes using microorganisms, isolated plant and animal cells, and enzymes.

Algenbioreaktor und Algenzellen (Haematococcus pluvialis) mit rotem Farbstoff Astaxanthin

Students can choose different emphases in their study program depending on their inclination. For example, they can choose subjects focusing on the apparatus engineering design and automation of biotechnical processes. Alternatively or complementarily, they can concentrate on content necessary for optimizing microbial production strains through targeted metabolic engineering.

This field of study suits students looking for a combination of biological and technical content. Graduates of bioprocess engineering are mainly employed in the (bio)chemical and pharmaceutical industries, where they translate the results of basic biological research into industrial processes.

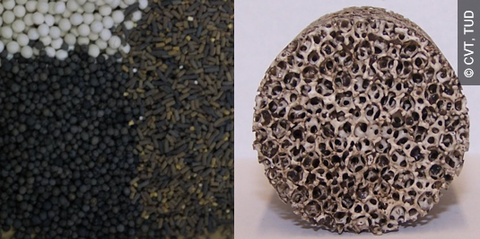

Chemical engineering technology, chemical engineering, or in English-speaking countries, chemical engineering are synonyms for the scientific discipline at the interface between natural science and engineering, which focuses on processes and plants in which substances are changed according to type, property, and/or composition, e.g., with the help of catalysts. The methods and plants are used to extract various materials and valuable substances from conventional and renewable raw materials and waste materials for multiple industries. The spectrum ranges from A for agriculture to Z for the cement industry.

During their studies, students of chemical engineering technology intensively deal with chemical fundamentals and processes in material conversion, material separation, and material combination according to chemical, mechanical and thermal principles. In addition to general engineering and unique process engineering content, lectures, exercises, and extensive laboratory practicals are explicitly used to impart knowledge and develop skills necessary for developing and optimizing chemical syntheses and associated separation operations. Students can choose different emphases in their study program depending on their inclination. They can acquire material- and process-related special knowledge for various branches of industry and alternatively or complementarily focus on thermodynamic fundamentals or phenomena at particles and phase interfaces.

The field of study is particularly suitable for students seeking a combination of engineering with natural science and, in particular, chemistry. In their careers, chemical engineering graduates research new processes and methods for producing various materials, valuable substances, and active ingredients, plan and implement associated production facilities, and operate, monitor, and optimize them. In addition to the chemical and pharmaceutical industries, the skills acquired are also required primarily in the cosmetics and care products industries, as well as in environmental, energy, and semiconductor technology, and apparatus and plant engineering. Graduates of chemical engineering thus find challenging and future-proof jobs in almost all industry sectors and make an indispensable contribution to the development of sustainable industrial production.

Wood and fiber materials technology encompasses three main areas of focus: Wood technology deals with the anatomical or chemical structure, physical properties, technical use, and processing of wood as a raw material. Fiber materials technology is dedicated to the extraction, modification, and processing of generally vegetable fibers into materials. Paper technology, in turn, is the field of expertise for producing and preparing paper fiber materials and their finishing.

With the increasing expansion of a sustainable economy based on natural resources, and the bio-economy, more and more new fields are being opened up for this purpose: Wood is by far the largest bio-based raw material source for use in products of all kinds. In this context, wood technology goes beyond craft-based apprenticeships to sustainably tap the potential of wood-based materials in technical industries. Individual interests can be pursued through a broad selection of scientific project work accompanying the course. In addition, employment as a student assistant is an often-appreciated opportunity to gain experience in the laboratory and with the state of diverse research.

Our graduates work in all wood processing industries, i.e., in particular the furniture industry, the pulp and paper industry, and companies that manufacture machines and chemicals for processing wood and composites from natural fibers.

In the seventh semester of the Diploma course Process Engineering and Natural Materials Technology there are no lectures. Instead, this period is reserved for a mandatory specialized internship, during which students can gain practical experience and apply their knowledge in industrial companies or non-university research institutions. The internship lasts 15 weeks and serves as an important orientation for the students and their subject focus in the further course of study. The program is completed in the 10th semester with the writing of a diploma thesis or in the 6th semester with the writing of a bachelor thesis.

Bachelor/Diplom/Postgraduate Studies

The Faculty of Mechanical Engineering at the TU Dresden maintains the classical engineering degree but has adapted all courses of study to the Bologna criteria for international comparability. The German Diplom-Ingenieur (Dipl.-Ing. 10 semesters) is a globally recognized title and quality term; it is well known in the business world and mainly established in the technical field. A diploma program lasts at least five years in the standard study period. After the first four semesters, an intermediate certificate confirms successful completion of the primary studies, the content of which is broad engineering and scientific fundamentals. After that, students in the diploma program can continue their education and acquire in-depth specialized knowledge in their chosen field during the remaining six semesters. The diploma program includes a technical internship in the 7th semester, which is completed outside the university. This internship allows students to gain practical experience in their future professional environment and apply their theoretical knowledge in industrial practice. After ten semesters, students achieve the professionally qualifying university degree of Diplom-Ingenieur. The comparability of the diploma and master's degree is confirmed for each graduate with the "Diploma Supplement". The diploma is, therefore, equivalent to a master's degree.

In addition to this training program, we offer a three-year bachelor's program (6 semesters), the content of which essentially corresponds to the first semesters of the diploma program. The bachelor's program allows students to enter the workforce earlier. However, it is primarily intended for those who, after completing a bachelor's degree at another university in Germany or abroad, would like to study for a master's degree.

The postgraduate program is our offer to all those who already have an academic degree but want to deepen their knowledge in one of our fields of study. The entry requirement is a completed degree (bachelor's, master's or diploma) in an engineering discipline. Our postgraduate program is therefore particularly suitable for those who wish to change their focus or sharpen their educational profile. After five semesters, students receive the professional degree of Diplom-Ingenieur. Comparability with a Master's degree is confirmed by a "Diploma Supplement", as is the case with undergraduate studies.

Structure

Click on the graphic to enlarge.

Application

We recommend that international students take a close look at the compact page on study orientation. Various requirements are listed here. You can find further important information and conditions about the study program, such as the study requirements or deadlines, in the central study information system (SINS).

Catching voices

Josi, a student in Process and Natural Materials Engineering - Portrait and Q&A

Josi is studying Process and Natural Materials Engineering with the field of study in Food Technology. In the portrait, she reveals what excites her about the field and how the program's flexibility will help you make the right choice of major studies.

"I have always enjoyed being creative in the kitchen. Chocolates, cakes, bread and yogurt - homemade not only tastes better, it has always been fun for me to realize myself in this way. But I wanted more. To know more, for example how filled chocolates, which take me hours to make, can be made a thousand times an hour. To understand more why milk is liquid but yogurt is solid. But do I want to spend a lifetime studying food, or is this just a phase? After graduating from high school, I wasn't so sure. The TU Dresden offers a very flexible course of study in Process Engineering and Natural Materials Technology. During the first four semesters, you have time to study general engineering subjects and to get a taste of various directions, such as biotechnology, wood and fiber technology, or food technology, before deciding on one of the directions. I am very happy with my choice to continue working with food. At the Chair of Food Technology, not only are basic processes taught, but also what is behind the processes. Of course, practice plays a big role in this. Many field trips, internships and tastings made learning easier. Current research is also not neglected. Above all, the holistic use and thus resource conservation and development of new uses for food is an important topic".

She reveals more about the course in the video.

Nora, Dario and Victor - This is how versatile the study course is

Nora, Dario and Victor talk about on what Process Engineering and Natural Materials Technology is about, which subjects you can specialize in and what prerequisites you should bring with you.

© TU Dresden

Uni-Vlog - Join Toni in her everyday life as a student

Studying is a full-time job? Not for Toni! In addition to her Studies at the TU Dresden, she is also the editor of the queering magazine for queer people. ✍️🏳️🌈 She also received the Deutschlandstipendium for her commitment! In the new university vlog, she gives us an insight into her colorful everyday life of canteen, lab equipment, and going to the cinema.

© Protagonistin und Dreh: Antonia Xenodochius Schnitt: Peggy Rudolph, Carola Queitsch

Evaluations of the study course

How satisfied are students in the study course Process Engineering and Natural Materials Technology? Studycheck.de provides independent evaluations of the study program.

General Advise on Choosing a Degree Program

Student advisory service for Process Engineering and Natural Materials Technology

© Tobias Ritz

© Tobias Ritz

Leiter AG Fernstudium

NameThomas Schön

Send encrypted email via the SecureMail portal (for TUD external users only).

Fern- und Aufbaustudium

Fern- und Aufbaustudium

Office hours:

- Friday:

- 12:30 - 13:30

Hinweise und Terminvereinbarung für Beratungsangeboten ist über OPAL-Kurse Studienberatung Maschinenbau Fakultät Maschinenwesen (https://tud.link/dnli) bzw. Fernstudium Maschinenbau (https://tud.link/r33xra) möglich.